stalling

Cheers Nuggit; I actually went back to his first post.....he a owns a T ace

not a fzr so X reference ing was not a good idea from me as its not required.

I also looked at other vendors and it appears that the t/ace bolt is just a plain set screw unit with a duel tool fitment.(hex head with X for screwdriver)

If this is the case ...any generic "bolt" that thread and length would suffice.

not a fzr so X reference ing was not a good idea from me as its not required.

I also looked at other vendors and it appears that the t/ace bolt is just a plain set screw unit with a duel tool fitment.(hex head with X for screwdriver)

If this is the case ...any generic "bolt" that thread and length would suffice.

Endeavour to persevere.

new clutch spring bolts on the way.

I managed to get a set of used carb rubbers off ebay for 20 quid inc postage which should be here tomorrow so hopefully that will be the high idle problem solved while I continue to do battle with the clutch.

Replacing carb rubbers should be something that even I can do without ballsing it up!!!!!!!!

I managed to get a set of used carb rubbers off ebay for 20 quid inc postage which should be here tomorrow so hopefully that will be the high idle problem solved while I continue to do battle with the clutch.

Replacing carb rubbers should be something that even I can do without ballsing it up!!!!!!!!

I don't want to pee on your bonfire thunder tax BUT you've just bought some used carb rubbers. Did you ask the seller if there's any cracks In them? If there is any cracks you've wasted your money. It will suck air in cause you more headaches.

Bit of advice. Buy a good bed and a good pair of shoes, because if you aren't in one you'll be in the other.

clutch

Use a stud extractor or.

I think the holes go all the way through, if so drill from the back and screw may well come out as its turning in the same direction as the drill bit.

Or you could try drilling a hole and applying heat to casting then tap a screw driver that will fit hole into place and unscrewing.

Be careful not to snap the tip of the screwdriver off in hole. So only apply light turning force to see if it moves, dont twist too hard.

Good luck hope all goes well

I think the holes go all the way through, if so drill from the back and screw may well come out as its turning in the same direction as the drill bit.

Or you could try drilling a hole and applying heat to casting then tap a screw driver that will fit hole into place and unscrewing.

Be careful not to snap the tip of the screwdriver off in hole. So only apply light turning force to see if it moves, dont twist too hard.

Good luck hope all goes well

Only those who have been insane can prove there not insane! Can you ??? :-)

http://paintings-by-des-pickering.weebly.com/

http://paintings-by-des-pickering.weebly.com/

First ; get rags and pack the area to prevent ingress of drill firings and metal chips.

Make exactly sure you centrepunch the exact centre of the broken bolt.

Use a good quality drill bit and slow speed with lubrication to drill a pilot

down the broken stud. 3-4mm pilot is usual.

Enlarge the pilot to 5mm using the same technique.

I am going against the norm now but engineering moves on.

Under NO circumstances use an easyout (reverse direction extractor).

They are far too brittle and if snapped in situ ;you are in a world of pain/expense.

Instead use a star or torx screwdriver bit slightly larger than the 5mm drilling gently tapped (hammered) into the broken thread.

Do NOT bash in a massively oversize bit; you only require a slight grip on the snapped thread.

Heat the outer of the boss where the stud is snapped into with a heatgun or wifes hairdryer.

You only need to expand the alloy a tiny amount if at all.

Now use something to turn out the torx bit including the broken thread.

I am fortunate in having T bar sets etc but an ordinary screw driver handle type would suffice.

If you had access to l/h drill bits it would come straight out as you drill the

broken thread, without requiring tools to gain a purchase.

It took longer to type this than it would take to perform the extraction, it really is that easy.

Make exactly sure you centrepunch the exact centre of the broken bolt.

Use a good quality drill bit and slow speed with lubrication to drill a pilot

down the broken stud. 3-4mm pilot is usual.

Enlarge the pilot to 5mm using the same technique.

I am going against the norm now but engineering moves on.

Under NO circumstances use an easyout (reverse direction extractor).

They are far too brittle and if snapped in situ ;you are in a world of pain/expense.

Instead use a star or torx screwdriver bit slightly larger than the 5mm drilling gently tapped (hammered) into the broken thread.

Do NOT bash in a massively oversize bit; you only require a slight grip on the snapped thread.

Heat the outer of the boss where the stud is snapped into with a heatgun or wifes hairdryer.

You only need to expand the alloy a tiny amount if at all.

Now use something to turn out the torx bit including the broken thread.

I am fortunate in having T bar sets etc but an ordinary screw driver handle type would suffice.

If you had access to l/h drill bits it would come straight out as you drill the

broken thread, without requiring tools to gain a purchase.

It took longer to type this than it would take to perform the extraction, it really is that easy.

Endeavour to persevere.

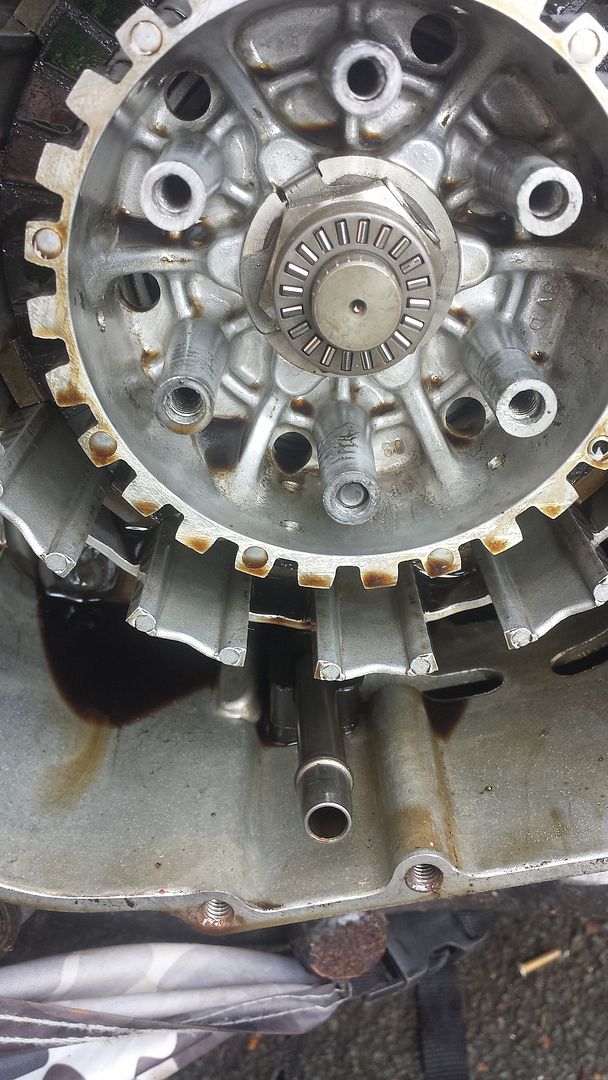

ok chaps. Got the offending sheared bolt out and changed the carb rubbers. I checked the replacement rubbers and althouh they are used, I couldnt see and splits or cracks.

thing is I am now back to square one. Tick over is still high and the idle adjustment screw doesnt change it. Also when I drop it into gear it stalls.

I am going to do an oil change tomorrow and take it from there.

thing is I am now back to square one. Tick over is still high and the idle adjustment screw doesnt change it. Also when I drop it into gear it stalls.

I am going to do an oil change tomorrow and take it from there.

Is the reassembled clutch disengaging the transmission. ?

If so you have NOT bypassed the sidestand and clutch safety circuits correctly.

The high idle could be;

Insufficient slack in throttle cable.

Air screw setting far too lean

Carb synchronisation screws so badly set that one or more carb butterflies are still open when the throttle idle screw is fully out.

Which method did you use to remove the broken clutch screw. ?

It is a good oil change that can cure mechanical issues !

If so you have NOT bypassed the sidestand and clutch safety circuits correctly.

The high idle could be;

Insufficient slack in throttle cable.

Air screw setting far too lean

Carb synchronisation screws so badly set that one or more carb butterflies are still open when the throttle idle screw is fully out.

Which method did you use to remove the broken clutch screw. ?

It is a good oil change that can cure mechanical issues !

Endeavour to persevere.

Who is online

Users browsing this forum: No registered users and 2 guests