going to clean the pistons and check tollerances tonight...as an aside has anyone replaced big and small end shell bearings on their fzr 1000?

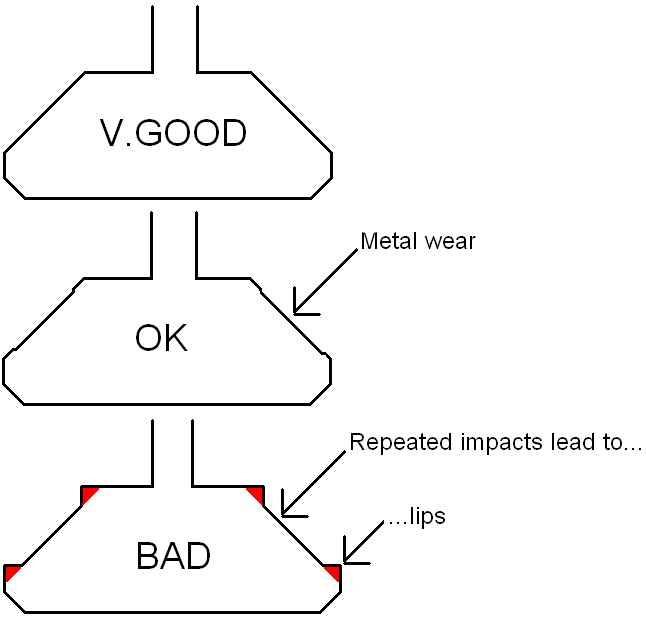

i have looked at the markings on the crankcase (they are something like 23654) and i have matched those up to the numbers on the side of the crankshaft, i have a list in my book at home of bearing shells and "colours" - is this what i need to rebuild the bottom end, so i would as for "2 yellows, a blue and 2 green"?? if you follow me?

likewise for the small end shell bearings, i have a similar list...confused i am, i am assuming a dealer knows what to order?

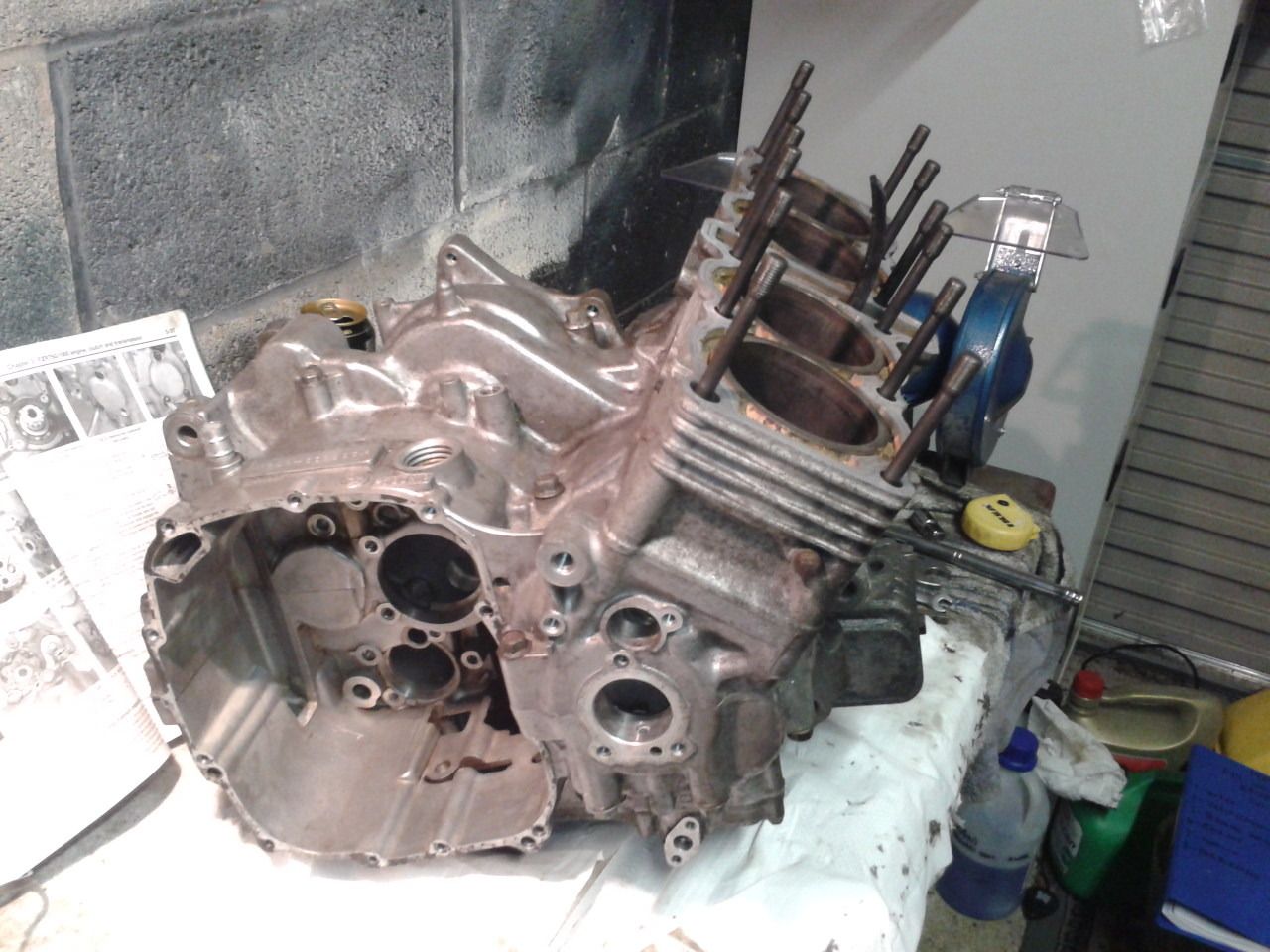

then the crank, conrods, pistons and shell bearings will be ready to go in, oil pump is cleaned, if i get time tonight i will also clean the oilpan, or i will at least strip everything off it, gear selector forks and shaft are also clean, i need to clean the oil feed lines, installing new oil jets, clutch cover is fully dissassembled and cleaned, need to remove a few bits of paper gasket here and there...so most bits are ready for assembly

crankcases and head are at my mates garage, he has another few bolts of someone elses bike to drill and helicoil so he will do mine at the same time, shouldnt be too long