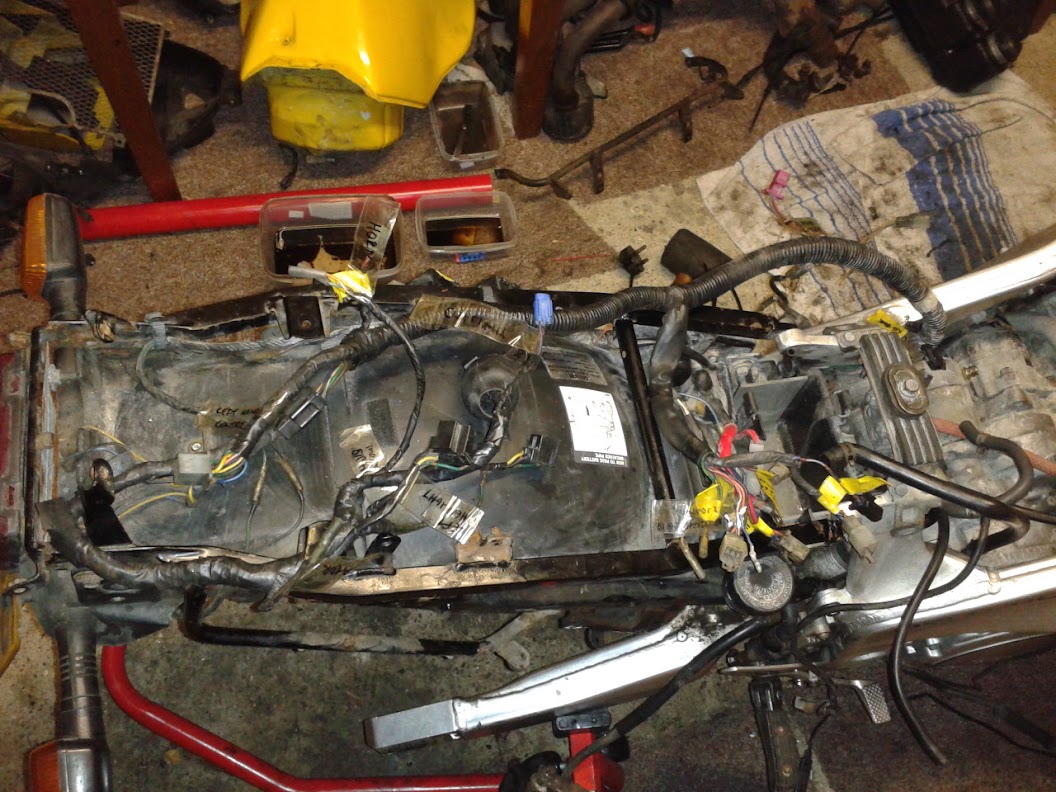

first thing will be to get a spark, it cranks fine, but no spark...i suspect its just a wiring fault/dodgy kill switch etc...once thats done it will get the loom hacked into

looking at a LiPO4 battery and custom case to centralise the mass, relocate all tail electrical relays etc to this new battery/electrics box. a friend suggested fitting a more modern pump and getting rid of the fuel pump relay - will look into this. Either gonna fit small bulb indicators, or wire in proper LED relays (as opposed to resistors).

am going to wuss out of designing a brand new look and basically copy this (

)...with a large matt black stripe running down the centerline of the bike and over the tail, with a matte red pinstripe either side, frame will be powdercoated black, downpipes will either be painted black, or wrapped in heatwrap, or both. mainly to keep them from getting damaged/corroded as they are in OK condition...but not fantastic, and new replacements with the EXUP housing i cant seem to find...only race systems without it...the general consensus seems to be to still stick with the exup valve...we will see.

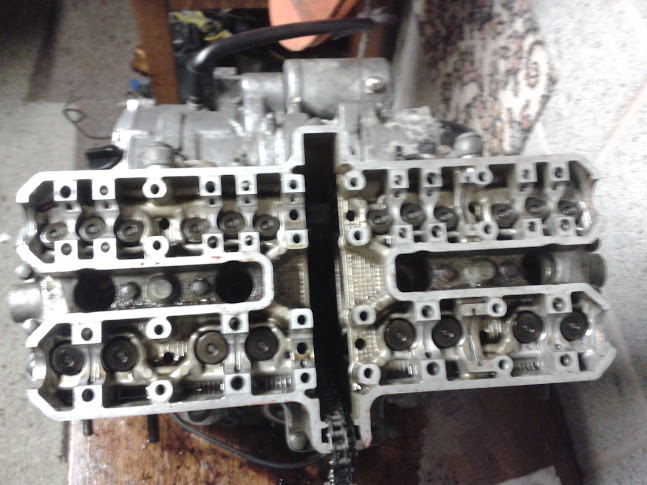

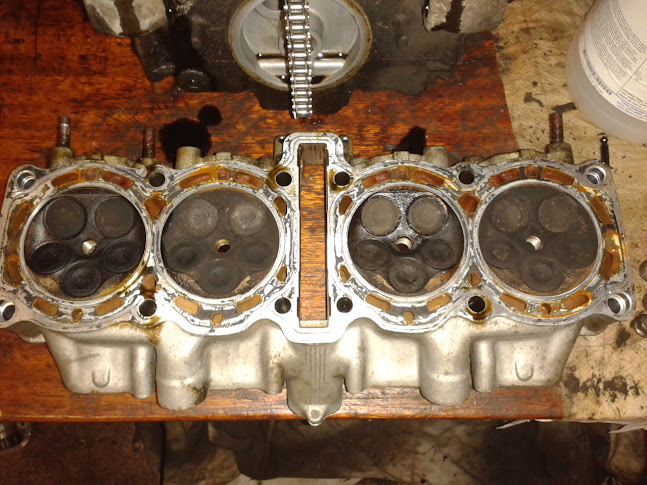

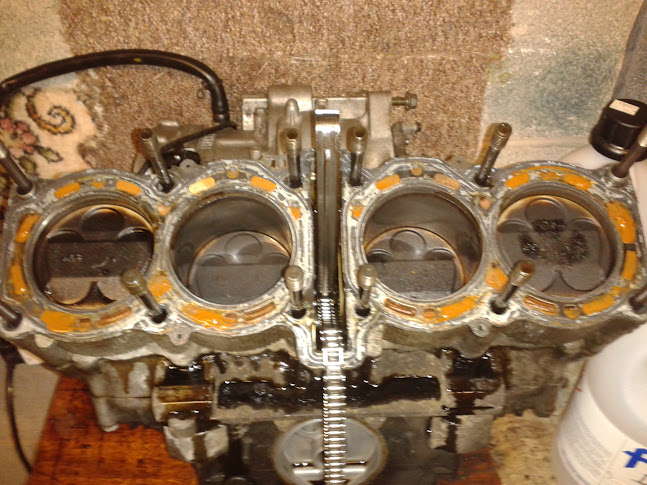

want to get the weight down, its about 236kg fully oiled and fuelled (apparently) and probably about 125bhp (46k miles on the clock, supposed to be 131bhp...), would like to get this towards the 200kg mark and ~140bhp mark. my zxr for comparison is ~180kg and 55bhp.

so thats 0.305bhp/kg for zxr, 0.529bhp/kg (stock fzr), 0.7bhp/kg (lightened fzr)

with me on board in gear +90kg:-

0.203bhp/kg for zxr, 0.383bhp/kg (stock fzr), 0.482bhp/kg (lightened fzr)

...so its got almost twice to power/weight ratio that my current bike has...should be good fun tearing the thing apart

)...with a large matt black stripe running down the centerline of the bike and over the tail, with a matte red pinstripe either side, frame will be powdercoated black, downpipes will either be painted black, or wrapped in heatwrap, or both. mainly to keep them from getting damaged/corroded as they are in OK condition...but not fantastic, and new replacements with the EXUP housing i cant seem to find...only race systems without it...the general consensus seems to be to still stick with the exup valve...we will see.

)...with a large matt black stripe running down the centerline of the bike and over the tail, with a matte red pinstripe either side, frame will be powdercoated black, downpipes will either be painted black, or wrapped in heatwrap, or both. mainly to keep them from getting damaged/corroded as they are in OK condition...but not fantastic, and new replacements with the EXUP housing i cant seem to find...only race systems without it...the general consensus seems to be to still stick with the exup valve...we will see.