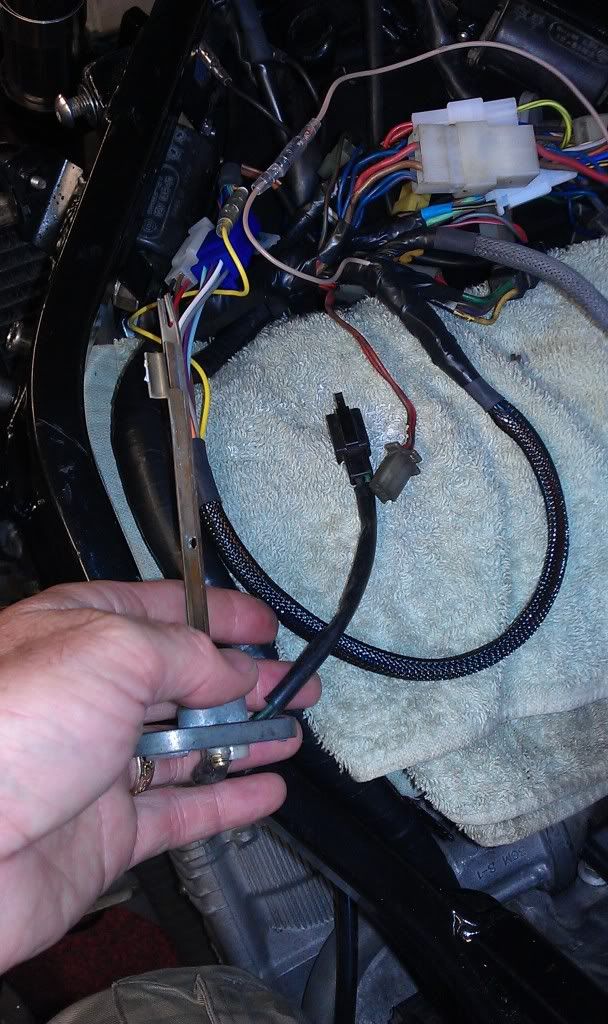

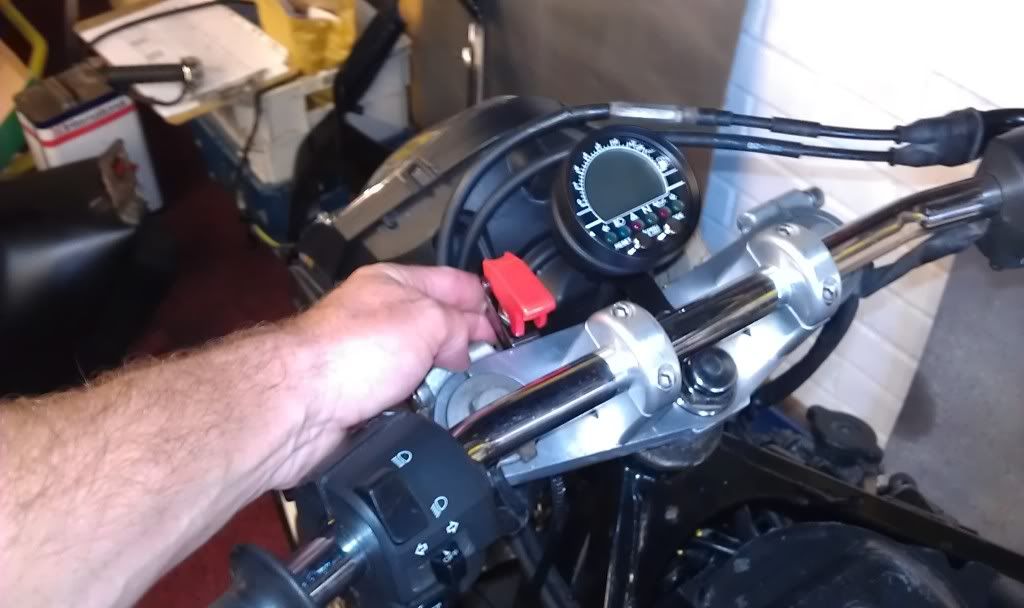

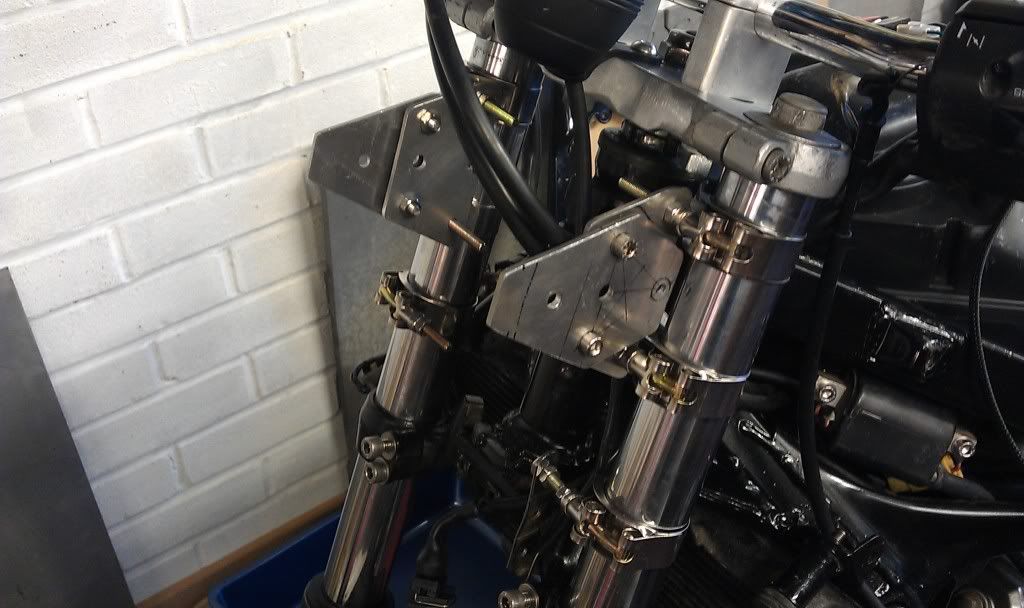

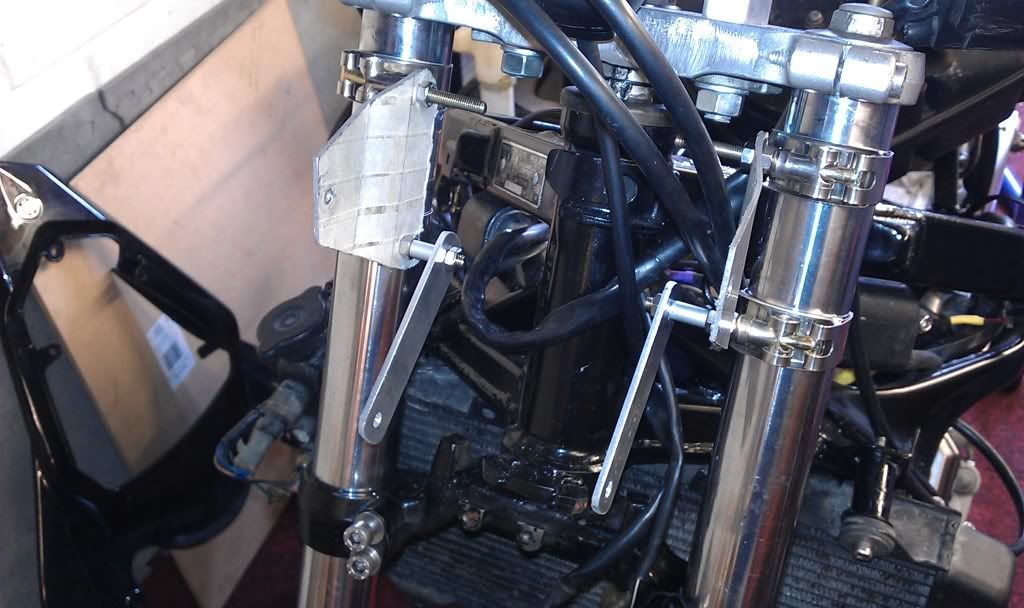

So, had a go at tidying up the wiring and decided to change the throttle for the original one the was on my Exup (fitted a quick action one a few years back) as the one that came with the FZ has a frayed cable.

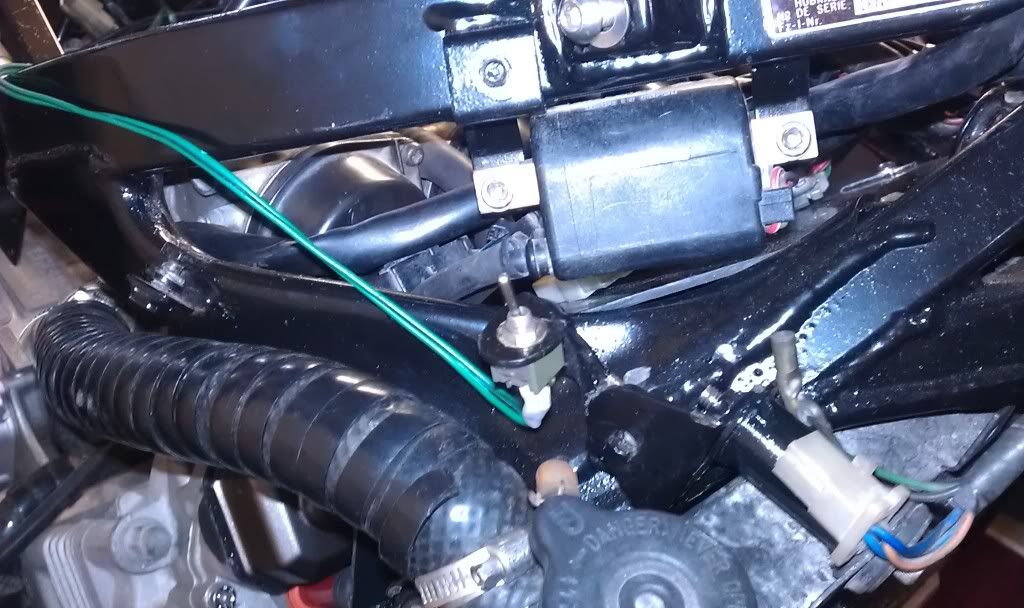

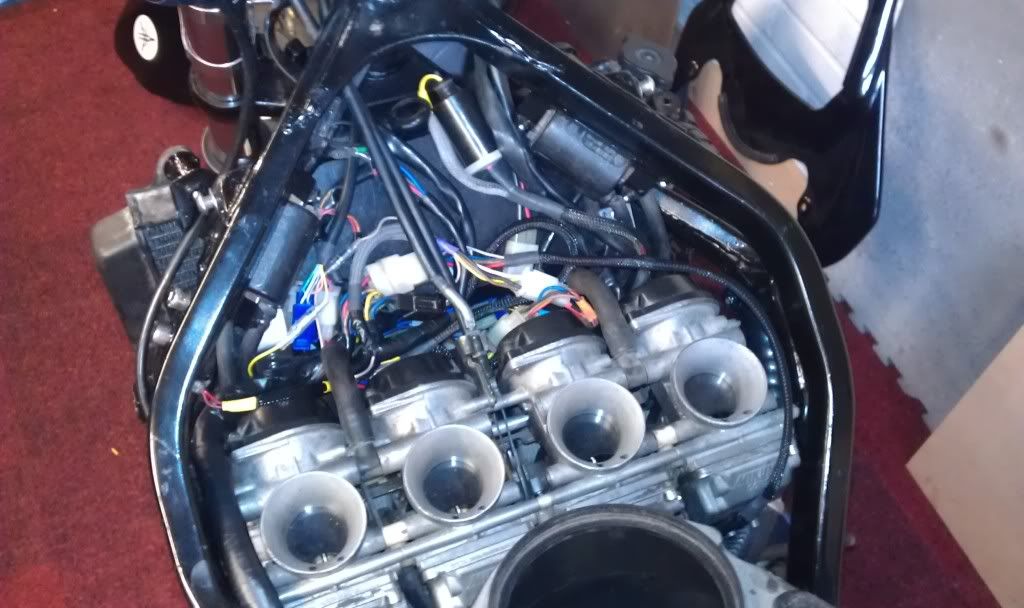

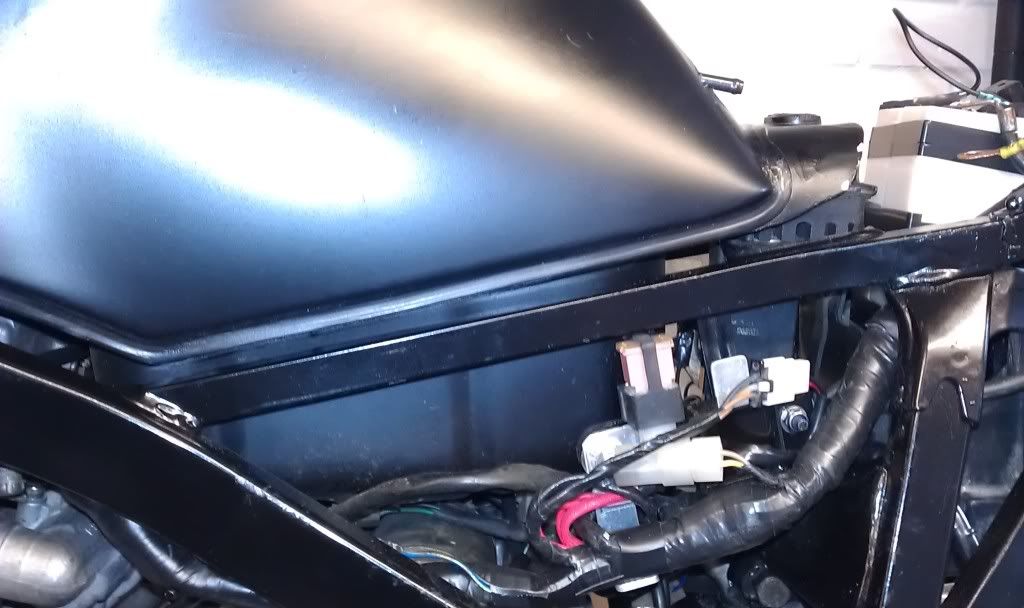

Wiring tidied, ish!

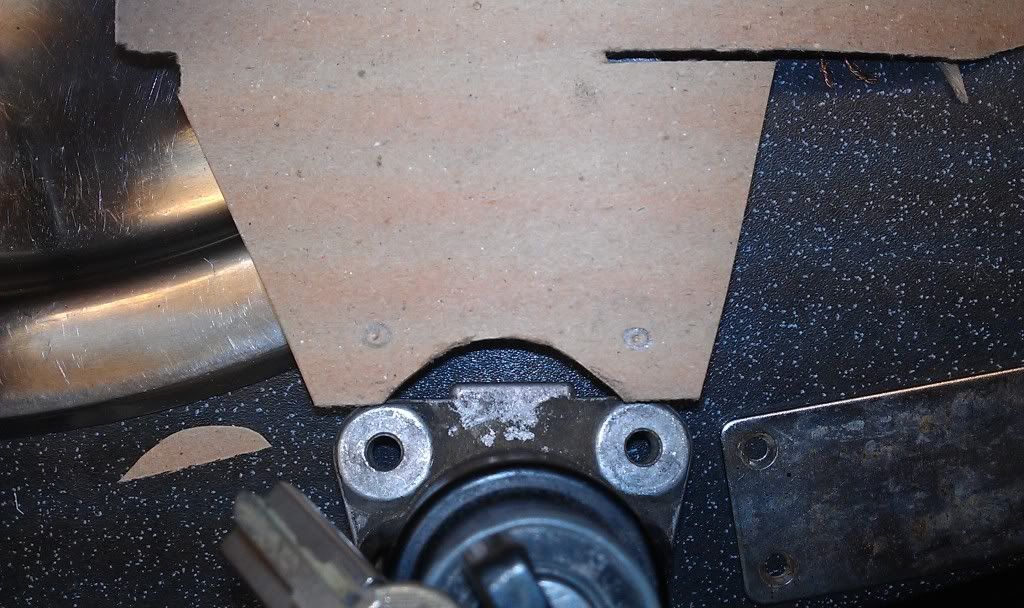

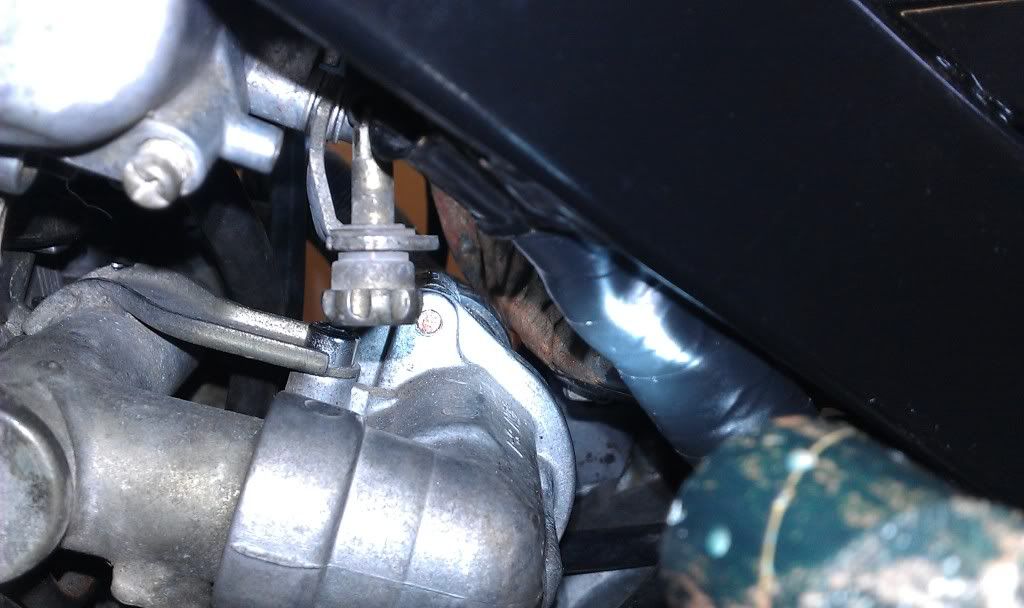

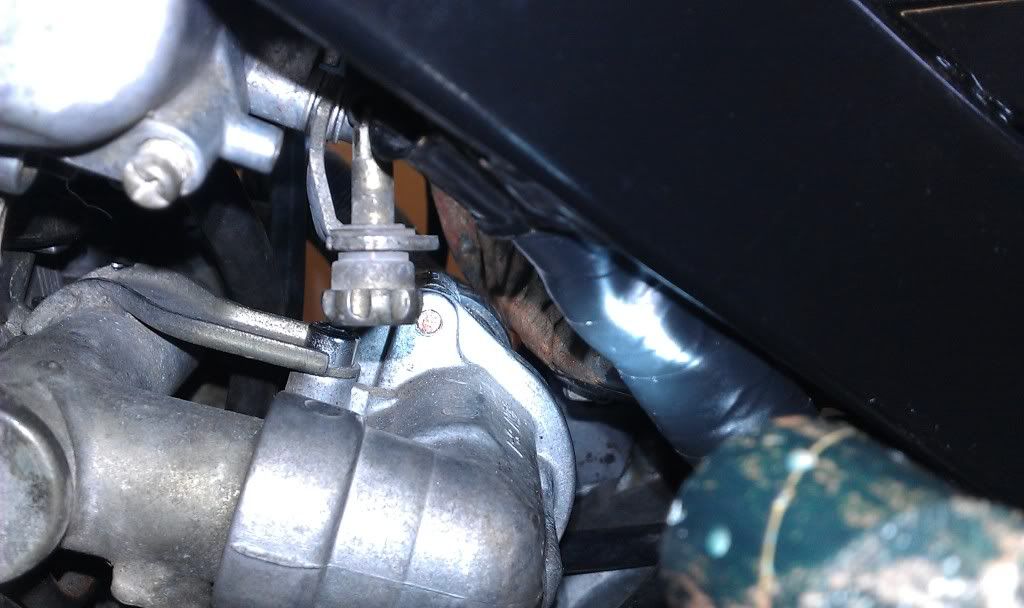

Whilst playing with the fuel tank it became obvious that the engine seems to sit in the frame slightly higher than it did in the other frame as the "modified" bottom of the tank no longer clears the thermostat housing!

Maybe the other frame WAS twisted??

Not obvious but tank is touching thermostat housing.

So to alleviate this situation the rear of the tank needs lifting.

Easy enough to do, just re-arrange some spacers.

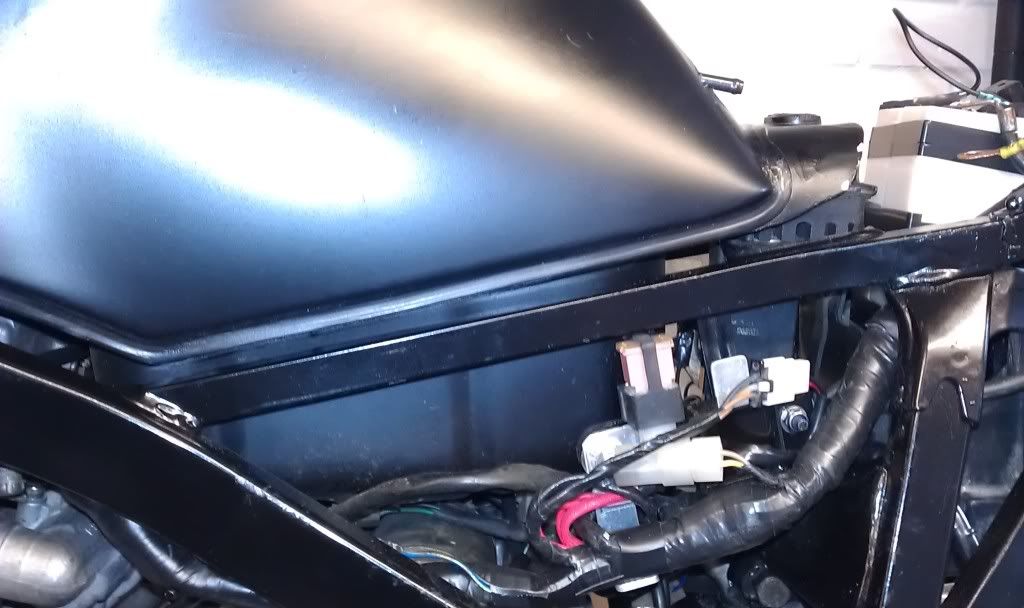

Clearance achieved

Doesn't noticeably alter the lines of the tank either which is good.

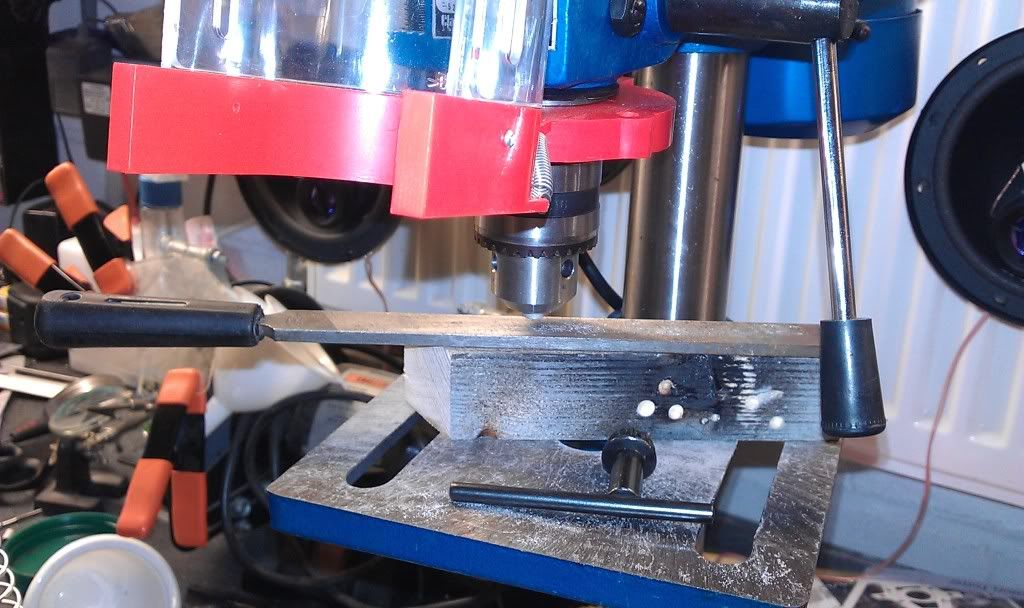

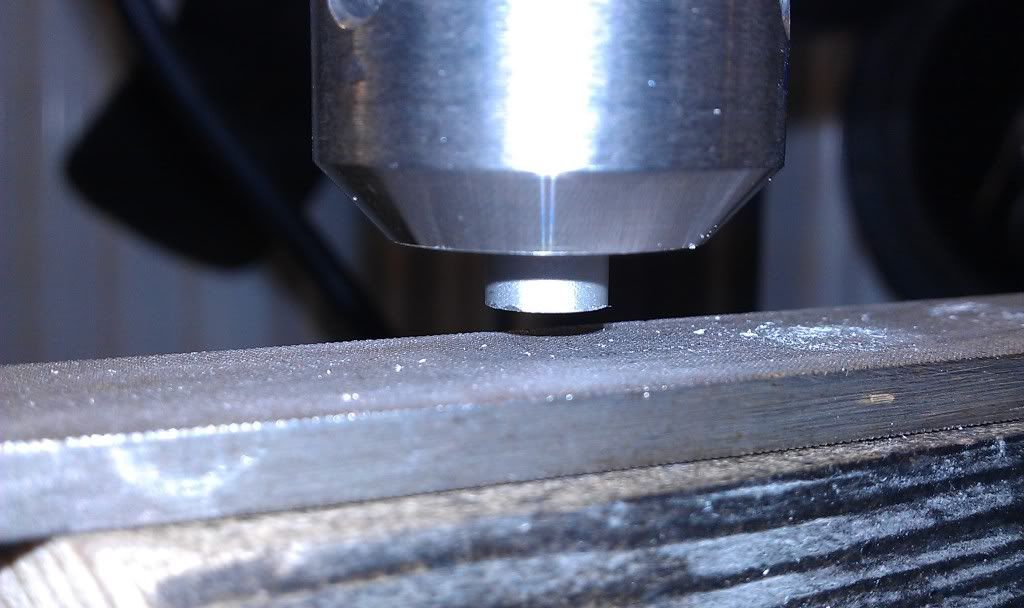

But that threw up another issue, the seat now sits high of the subframe because it rests on the tank, which has now been raised, so out with the hacksaw!!

This has since been neatened up and smoothed off.

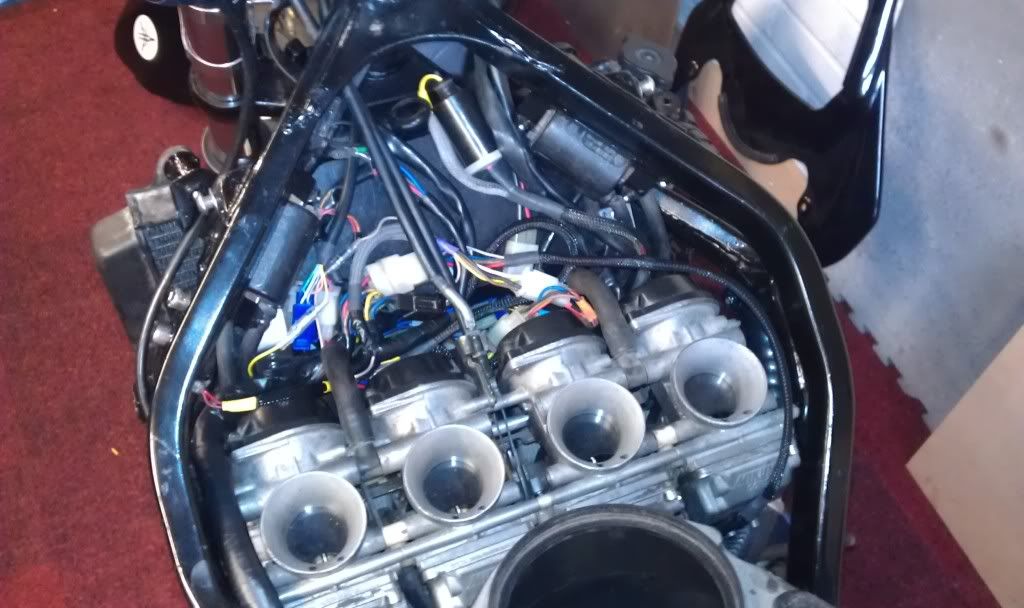

Anyhow, next on the agenda is trial fitting of the airbox.

With a little rearrangement of the throttle cables and wiring underneath it "sort of" fits.

The issue being the front edge of the inlet rubbers wont fit over the carbs.

As these are Exup rubbers fitted into a modified FZ airbox they fit too close to the box.

To give a bit of extra fitting wiggle room the would need to fit like this (rubbera pulled out of airbox)

as they fit over the carbs no problem when not installed in an airbox.

I thought about making up some spacers to glue/ weld into place but then remembered It just so happens that I have another airbox.

As you can see the original airbox has had its holes enlarged.

Using the original airbox the rubbers fit too loosely at the "ideal" position and dont seal with the box, but it just so happens that when I had a trial fit of the Exup rubbers in the smaller holed FZ airbox they fit snuggly upto the first lip...............bonus!!

So gave them a clean and assembled my mish mash.

Good job it was sunny today as after 10 mins in the sun the rubbers where nice and pliable and easy to squeeze into the 750 airbox.

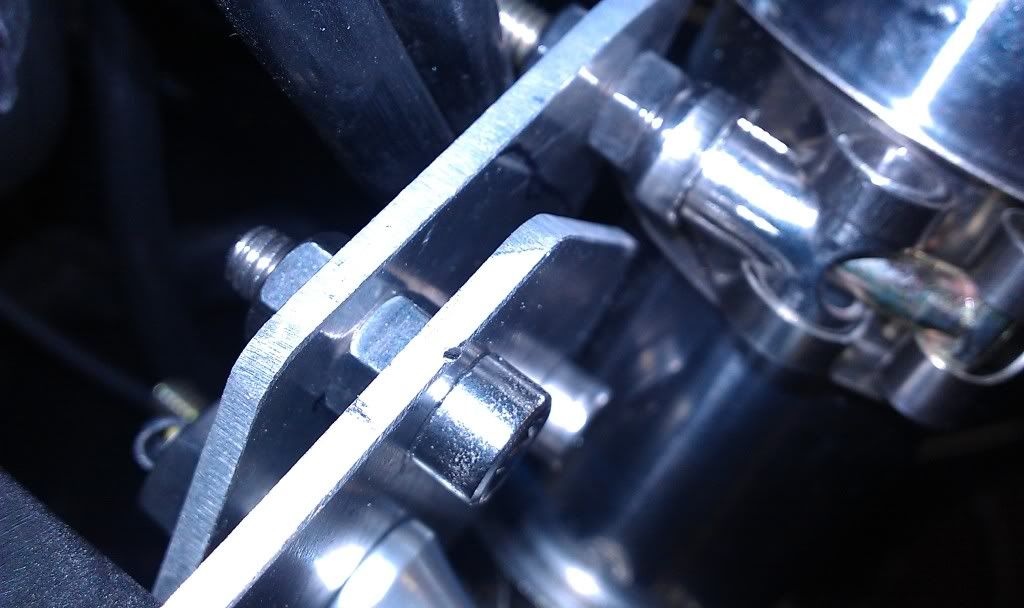

and with the extra wiggle room they fit nicely on the carbs

so out with the stainless bolts

And due to the raising of the rear of the tank earlier there is also no issue with the tank fitting over the airbox.

Installed some of the fuel line that I purchased earlier.

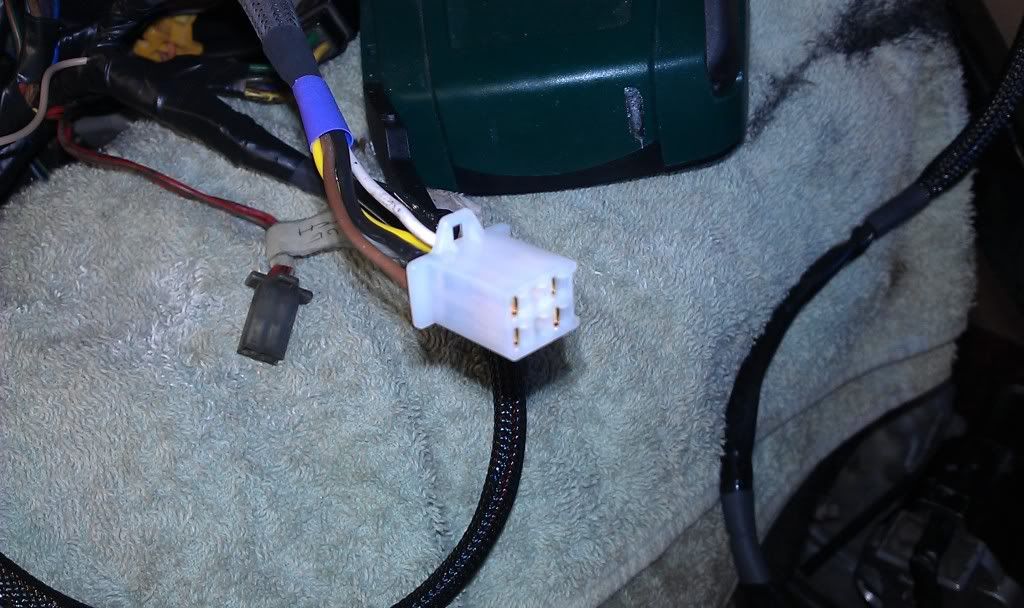

Next thing on the list was to double check my theory on the fuel light/reserve switch situation.

So I rigged up a bulb across the fuel pump so that it lit when the pump was "live"

and connected the fuel tank sender, but ran the bike off my carb balance rig, this way I dont have to fill the real tank to the reserve level, but as its connected the bike shoul act as if on reserve.

And as an aside it also gave me the chance to test the tacho function on the Acewell, which worked, whoop whoop!!

Tacho Video

Reserve function test.

Basically when started in reserve mode, as is the case, the fuel light should come on, the pump goes off line (telltale light goes out) until the reserve switch is operated.

Which is exactly what happend, I am a very happy bunny!!!! Also with the fuel tank resting on the floor against the bike the fuel level arm swung to its upper limit which was replicated by the fuel gauge on the Acewell!

Reserve operation Video. (I hate my voice

)

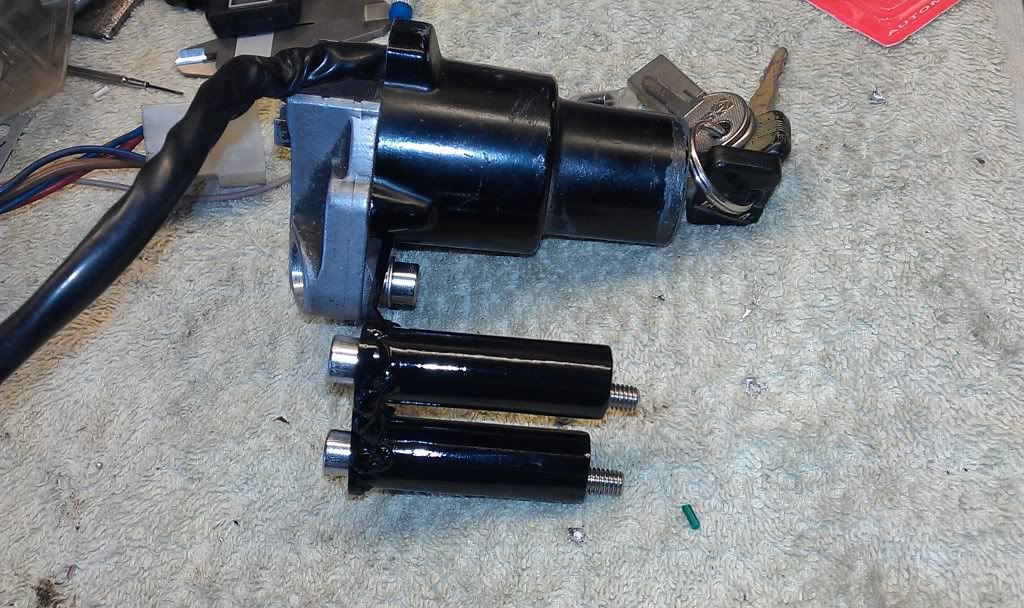

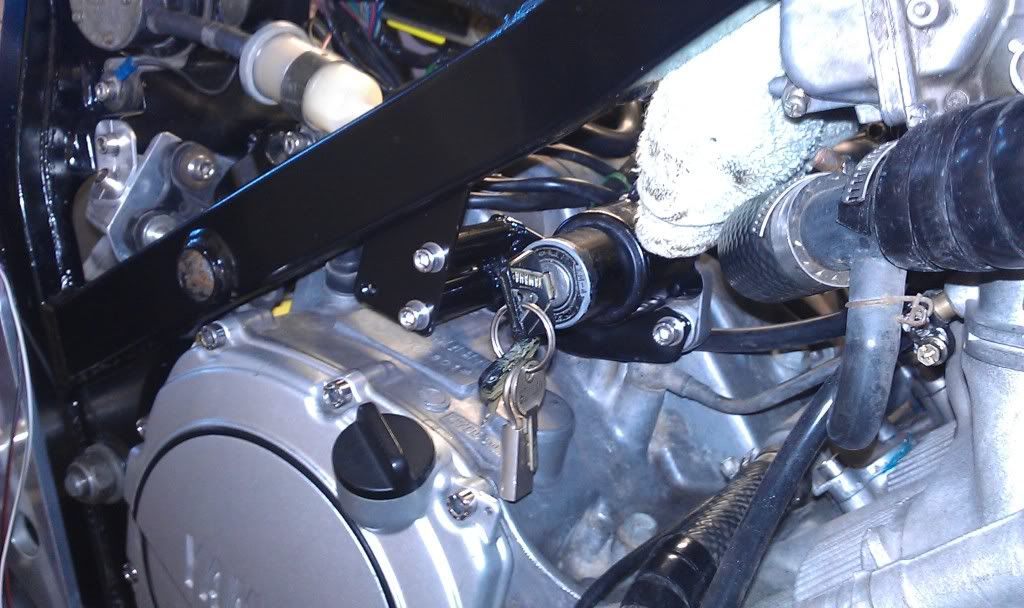

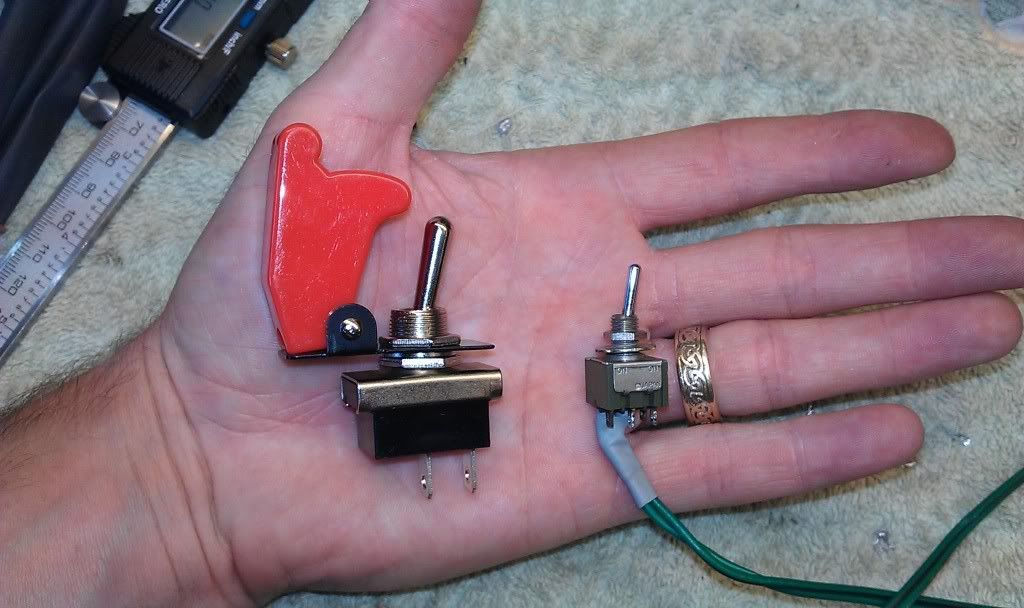

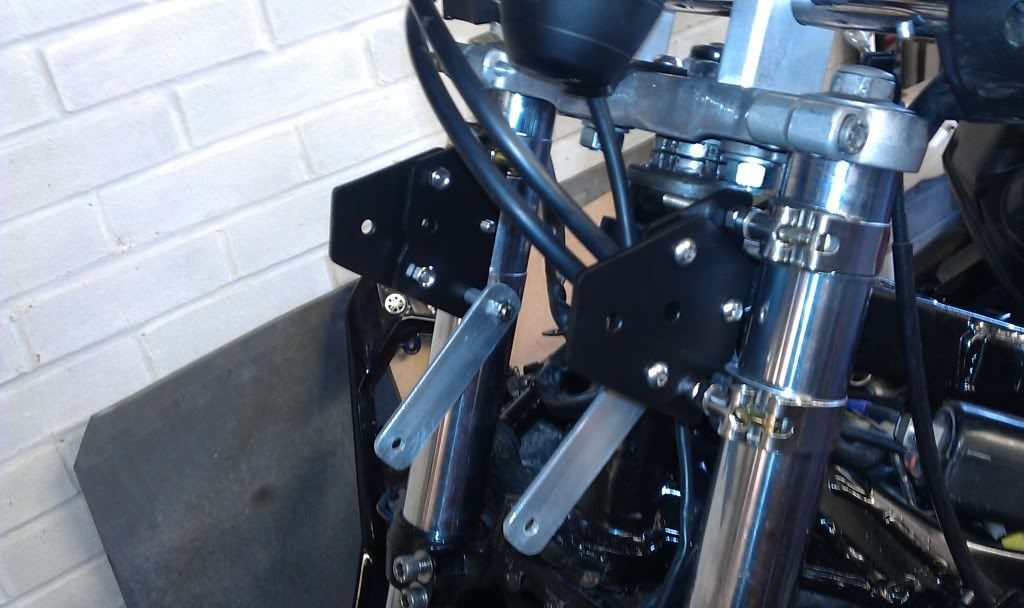

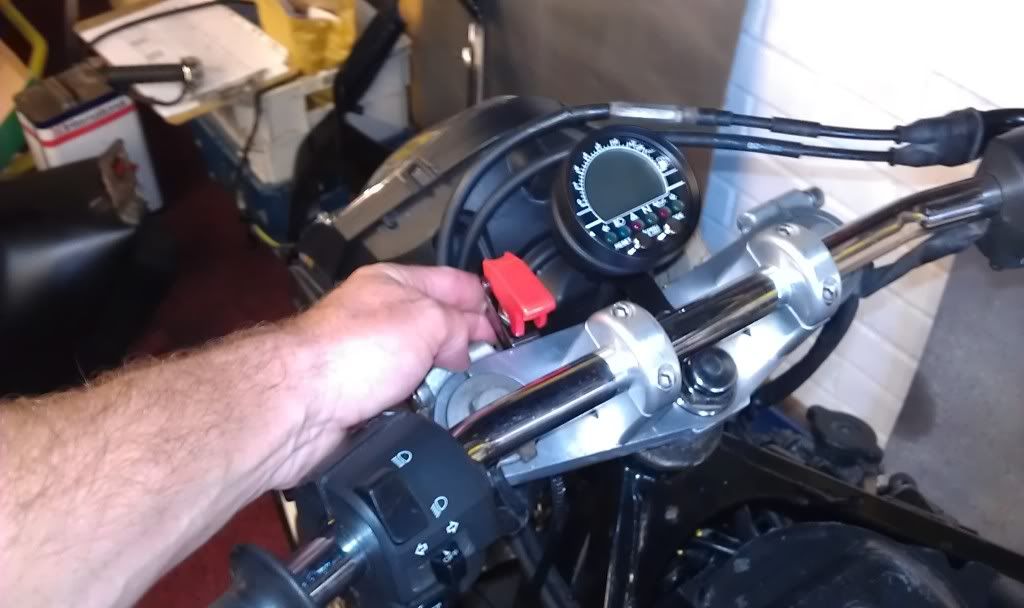

Might just mount the reserve switch here, not sure yet.

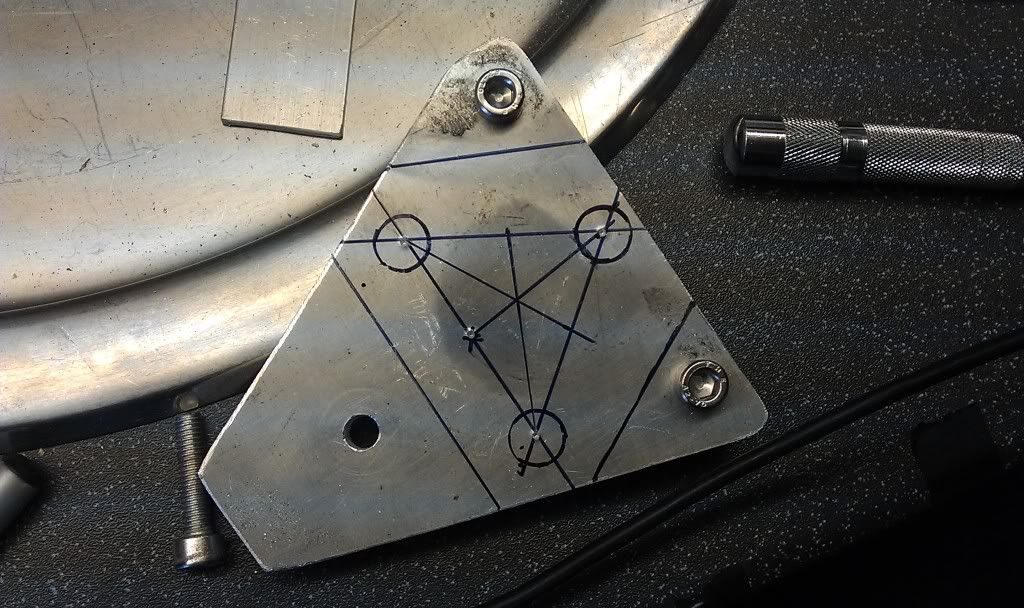

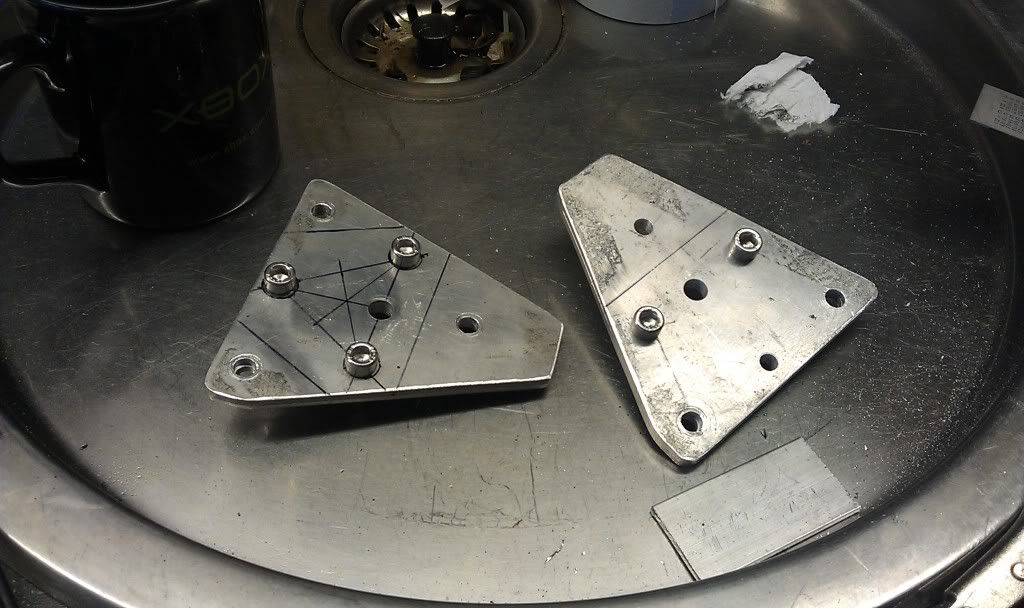

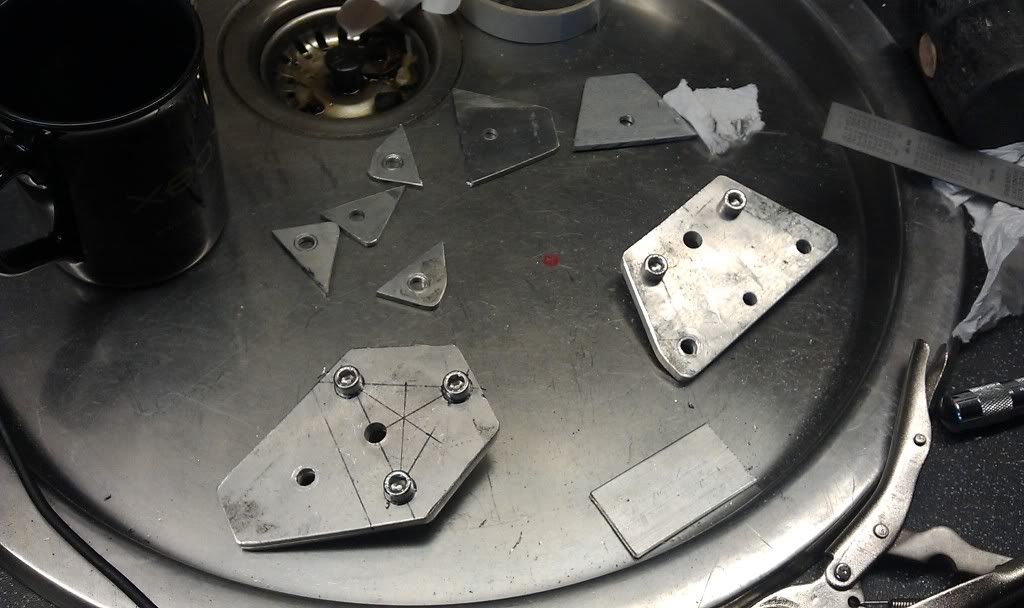

Anyhow thats todays escapades, once I have manufactured some other headlight brackets and mounted the indicators I can put the airbox on once and for all and leave the electrics behind for good