Right, now that I could run the beast without it oozing petrol all over the place I set about trying once and for all to sort out the electronic reserve side of the system.

The way it works is as follows.

There is a sensor (thermistor) in the tank, when it is covered by fuel it's kept cool so has low resistance and 11v flows along the attached wire (Green White)

At one end of this wire is the pump control relay and at the other is a fuel level light.

The light is connected between the Green and white wire and a switched live.

So when fuel covers the sensor there is a voltage difference across the bulb of 1v, so not enough to illuminate it.

But as the fuel level drops and the sensor is exposed to air it heats up, thereby increasing its resistance and causing the voltage in the green white wire to drop from 11v to 3.8v which in turn increases the voltage differance across the bulb, causing it to illuminate.

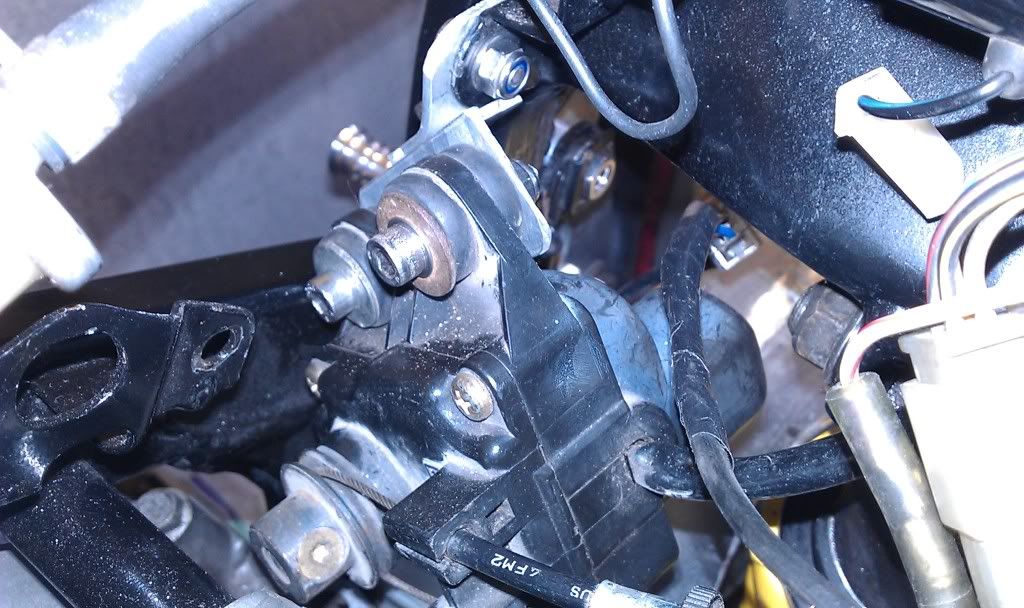

This voltage drop is also sensed by the pump relay which cuts the power to the pump until the reserve switch is operated (switch is open for ON position and closed/connected for RES)

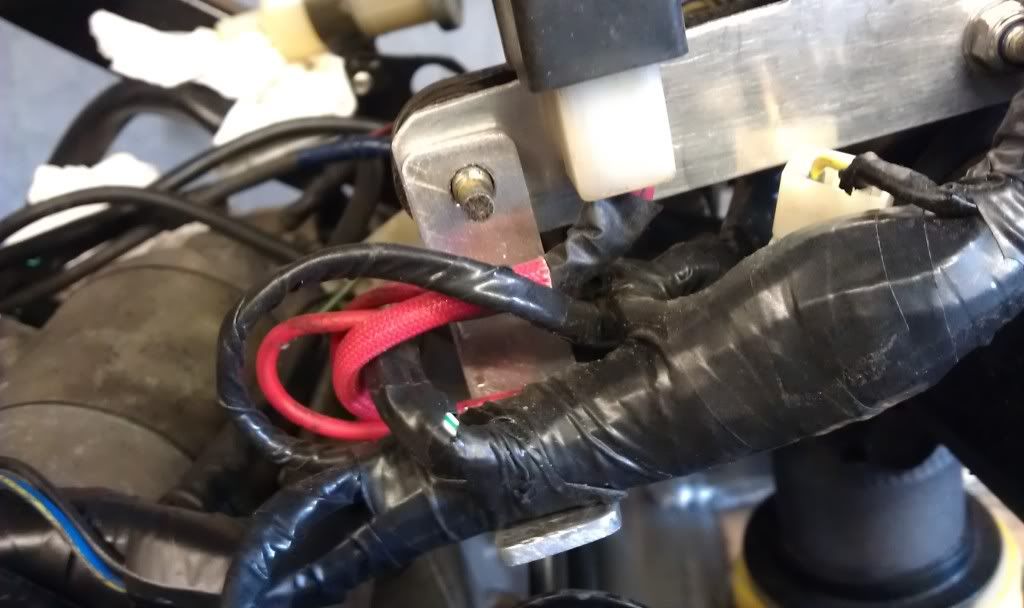

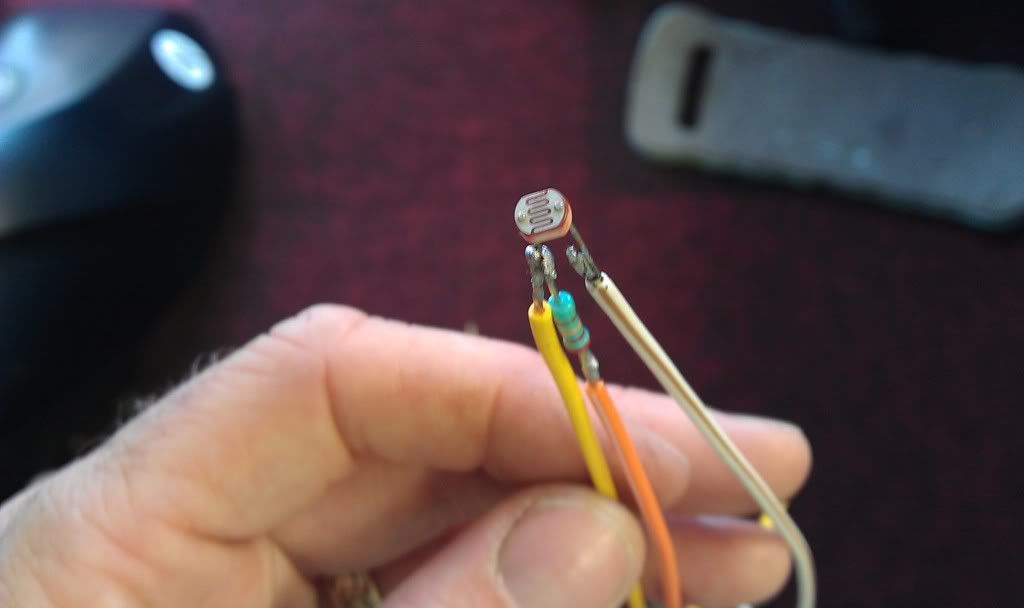

This was the theory, but as the previous owner had fudged the wiring to the tank and the sensor was duff (open circuit) the only way I could test this was to use the sensor from my Exup.

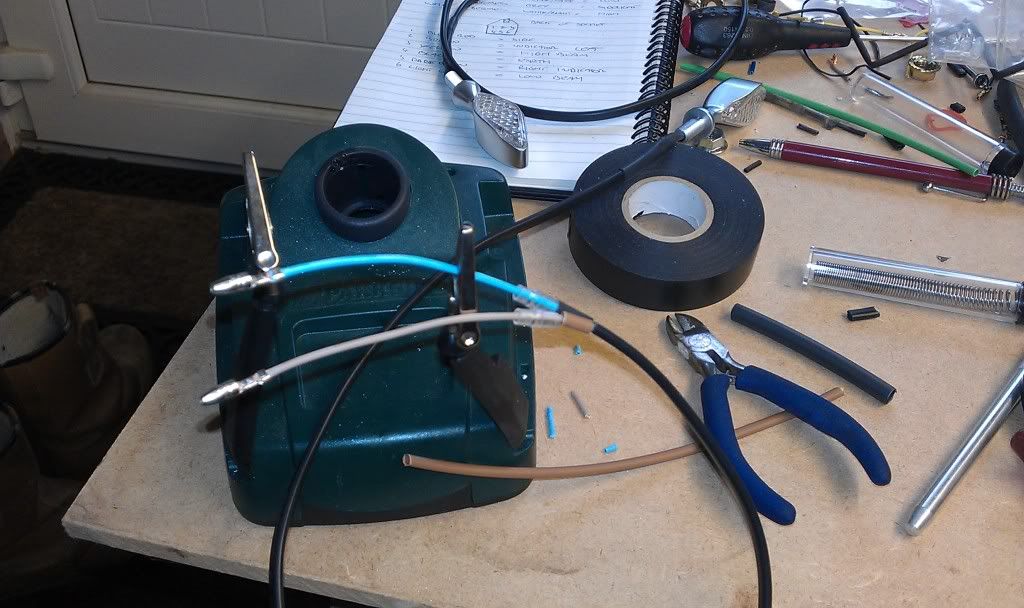

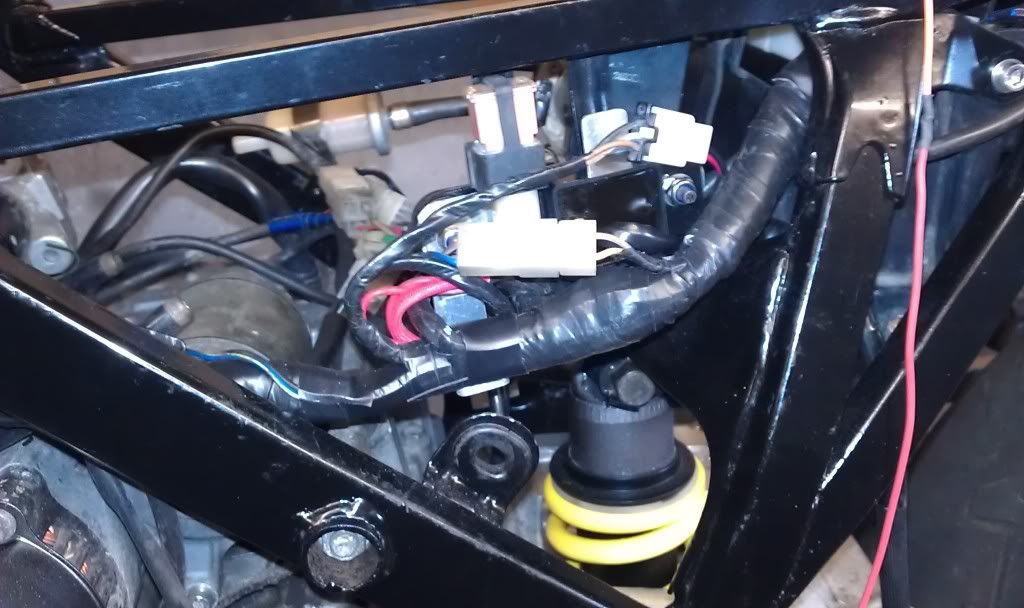

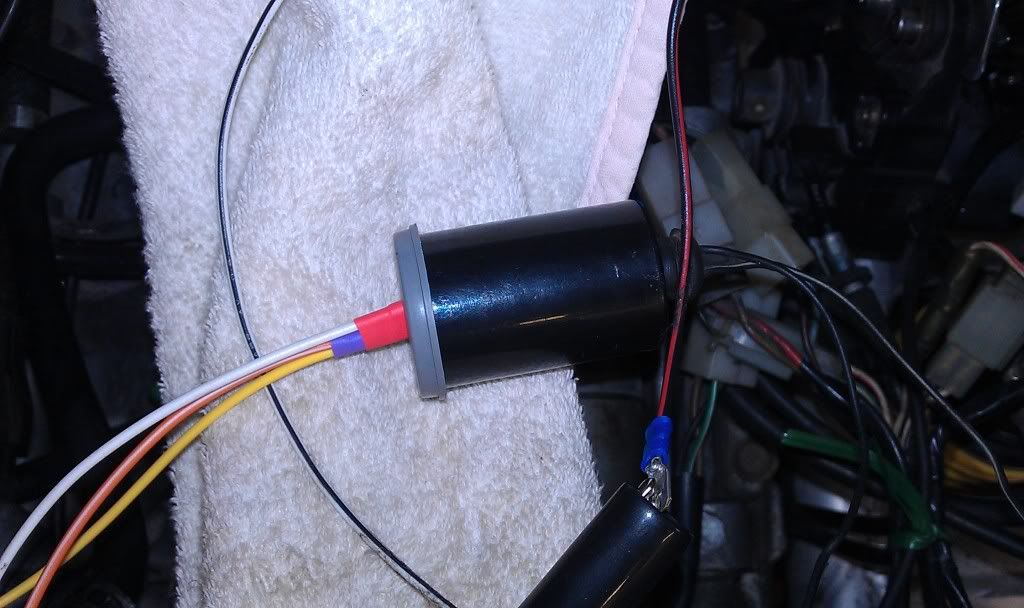

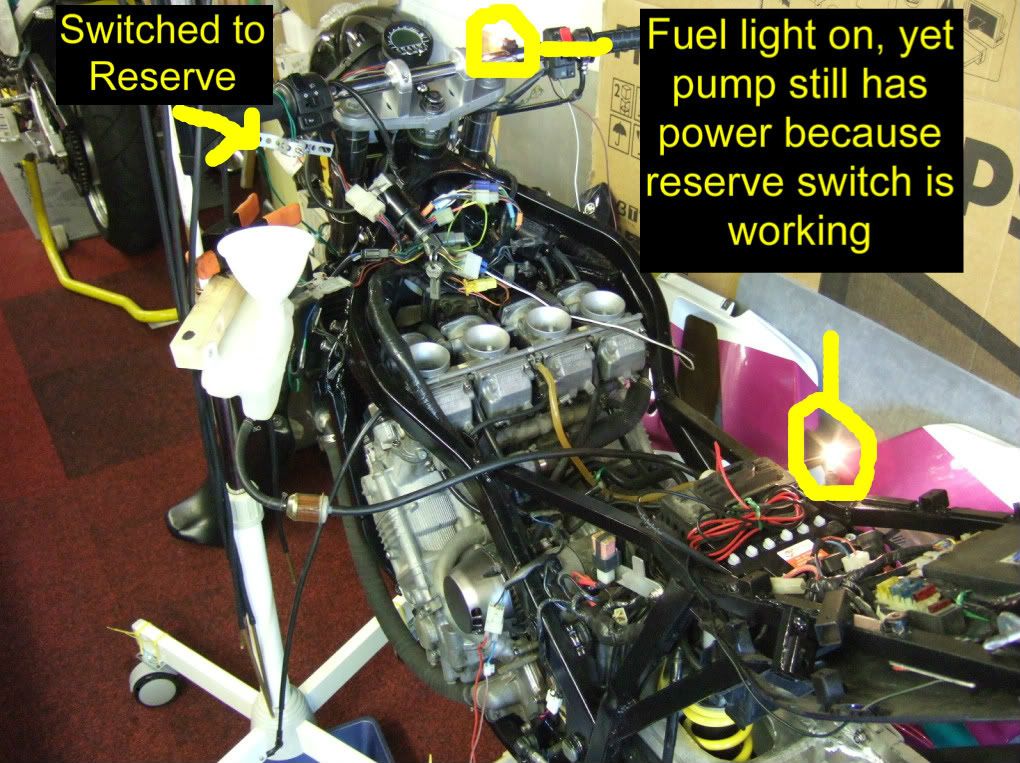

So, i rigged a bulb up across the fuel pump so I could see when it was recieving power

Located the correct wiring for the fuel level light and added a makeshift one.

Found the reserve switch wiring and added a switch

Added the sender from the Exup and ran a proof of theory test.

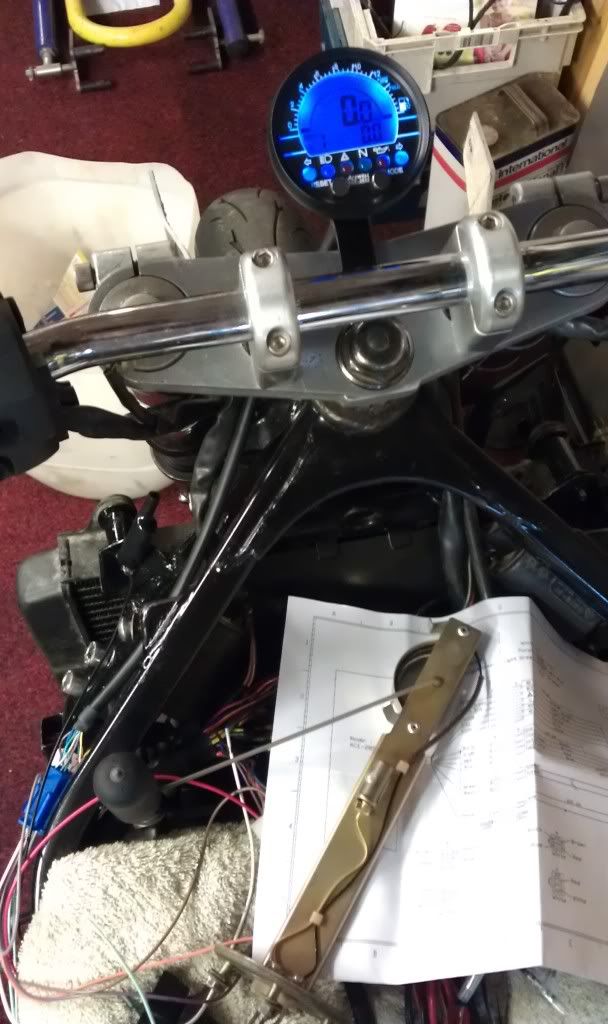

So with the sensor exposed to air, the fuel switch in the on position and the bike running the following should happen.

The bulb across the pump should be on, the fuel light should come on, followed by the pump light turning off, simulating run out of fuel.

Success, the above happened.

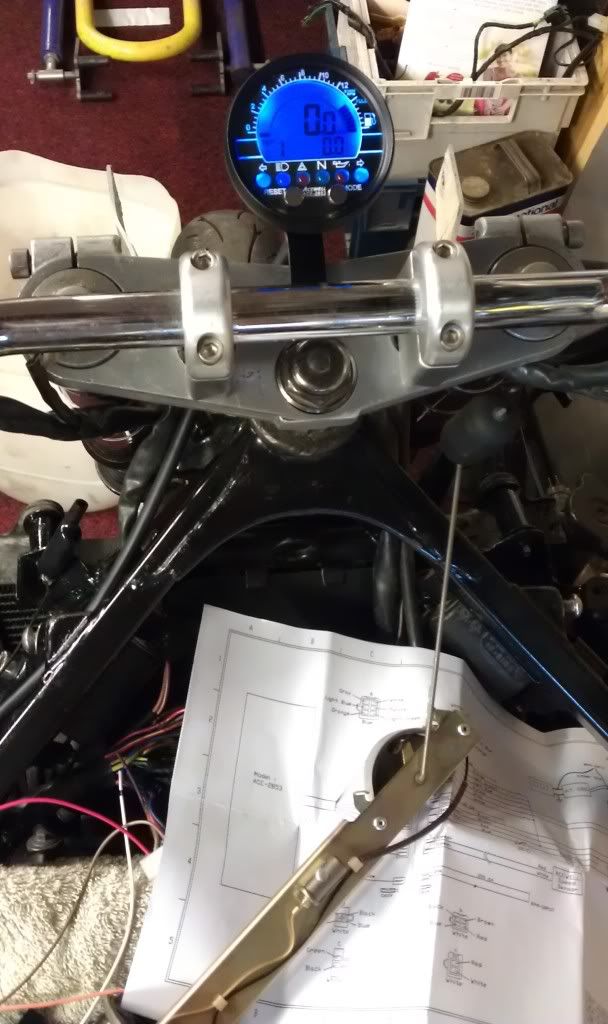

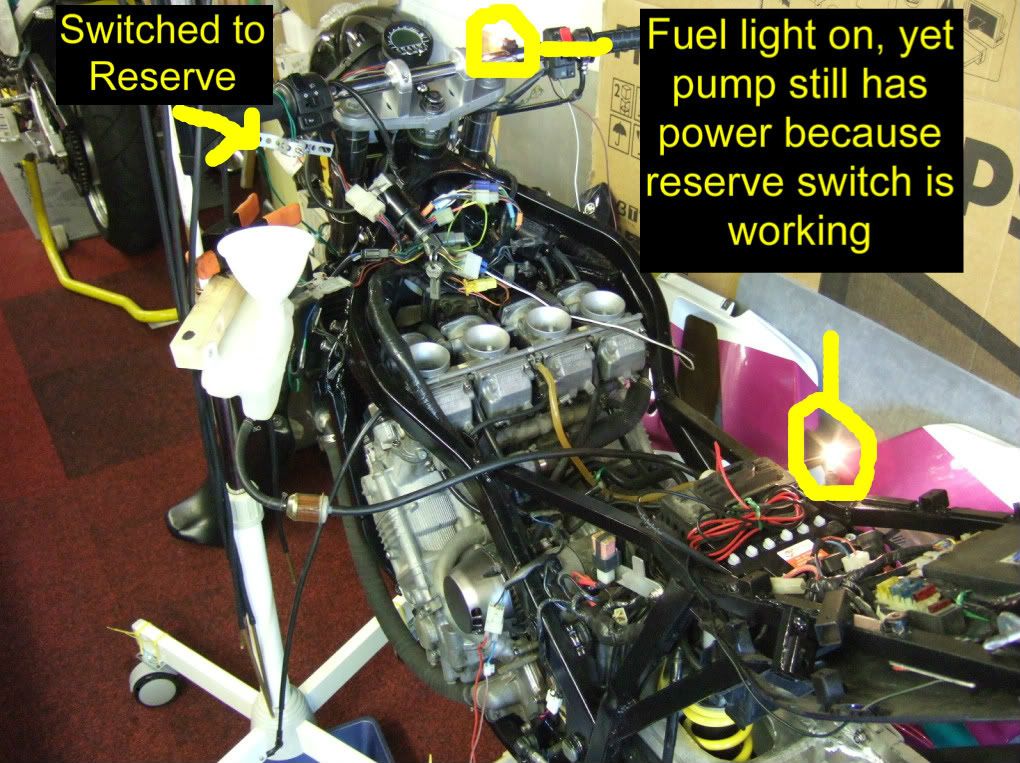

Next theory being that when I flick the switch to reserve power to the pump should return and the pump bulb should illuminate, obviously with the fuel light still lit.

Again success, so we are now effectivley running on reserve.

Final test is to immerse the sender in petrol therby simmulating a full tank of fuel which should cause the fuel light to go out yet power remain to the pump.

Again success

So I now have on its way to me a fuel sender from an Exup that I can use to replace the sender in the FZ tank, and have a fully functioning reserve with fuel gauge and fuel level light, bib and braces and all that.

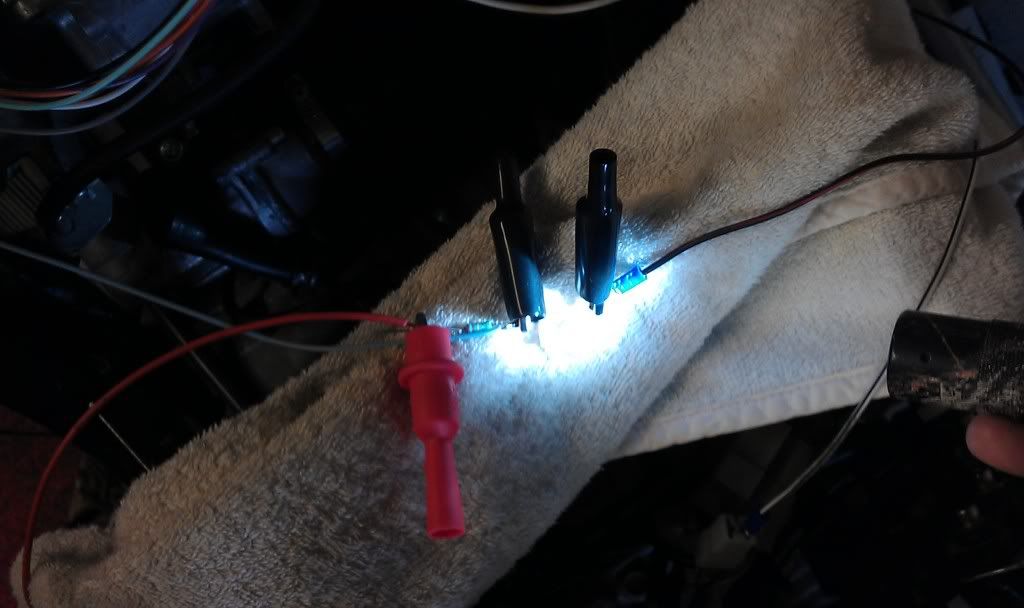

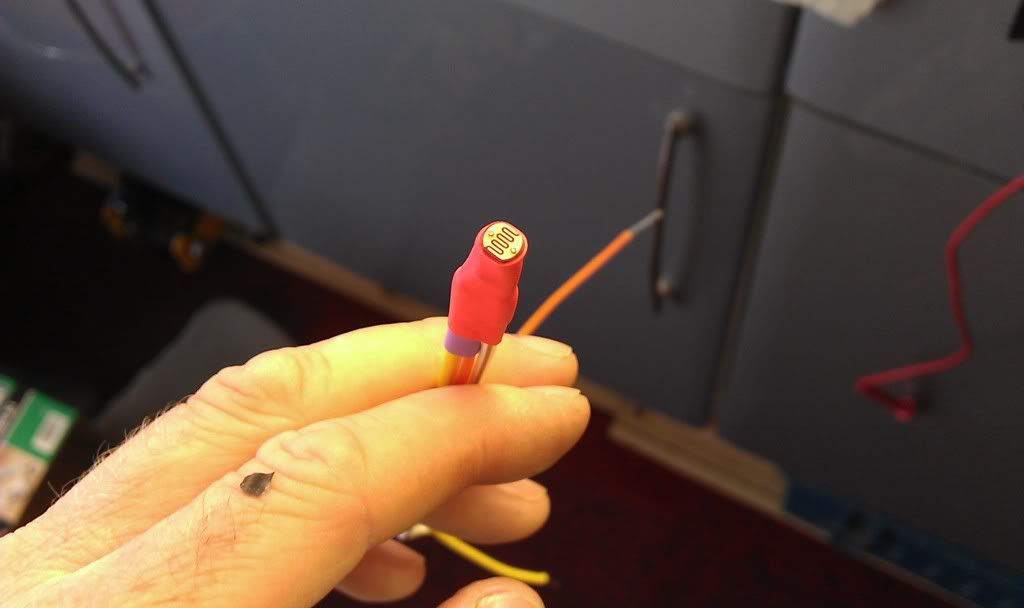

There is one slightly concerning thing I discovered though, its just how "warm" the sensor gets when not cooled by petrol.

This was after a minute's exposure to air, vid below.

A bit disconcerting but I tested it on the Exup incase it was due to different wiring or voltages, but its the same so try not to think about it next time you fill up after running on reserve for 6 miles or so.

The one final thing I have to do is make a photoresistor relay so I can use the fuel light to turn on the "hazard" LED in the Acewell, but I'm investigating this as I type.