Another day, another update, as mentioned yesterday I thought I'd tackle the number plate mount today.

AND YES I WILL MAKE SURE ITS STRAIGHT

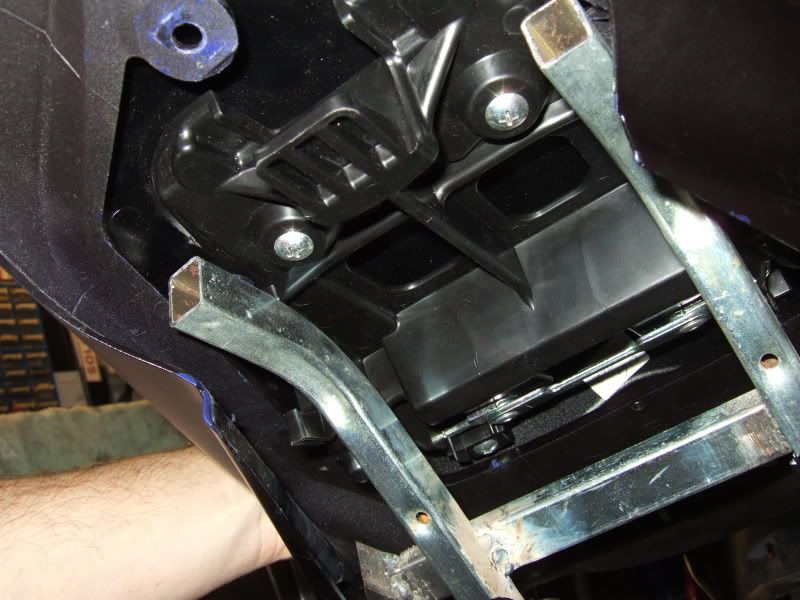

The idea was to attach it to the cross brace with bolts so as to make removing the tail unit simple.

The problem being the unit slots into itself at the rear light end, therefore making it akward to fit as its "hinged" at one end, not a top and bottom that are bolted together, so the two halves have to by pryed open enough to feed it over the sub frame.

This can be done at the moment but a welded on number plate mount would prevent this.

So started with a cardboard template to see what I could come up with.

I was going to make it out of Ally but didnt have anything thick enough, and seeing as the actual "tail tidy" underneath the bodywork may have to be legthened to avoid the plate hitting the rear wheel, theres going to be a fair amount of force exerted through it.

Then I remembered that I had purchased a tail tidy on Ebay about a year ago when I was amassing parts

Its doesn't extend far enough rearwards for me but its made from stainless, plenty strong enough,and has 6mm threaded inserts in it so it can be bolted from inside the subby.

So, with a little alteration,why not turn it upside down and use this as the mount inside the subframe.

So back to my box of offcuts to look for suitable donor items, went for a nice couple of 8mm lugs with a vintage of around 86 , should compliment the overall appearance nicely

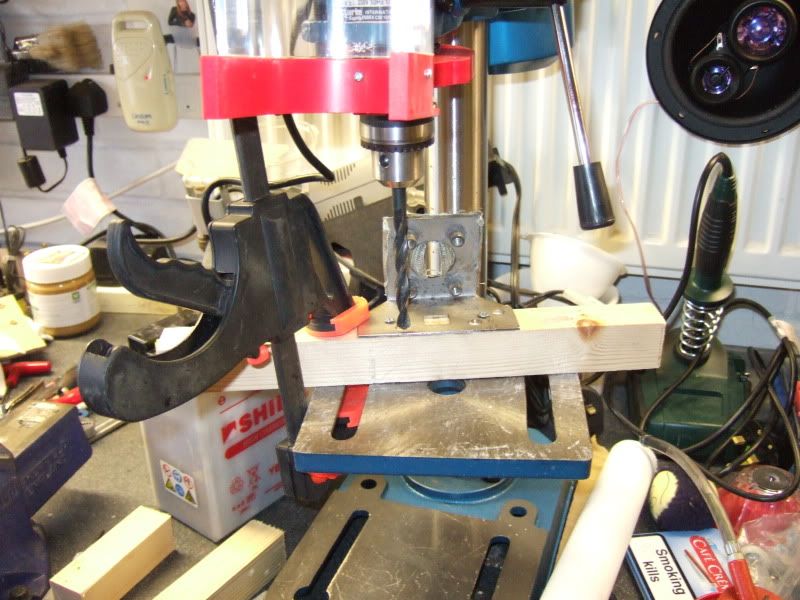

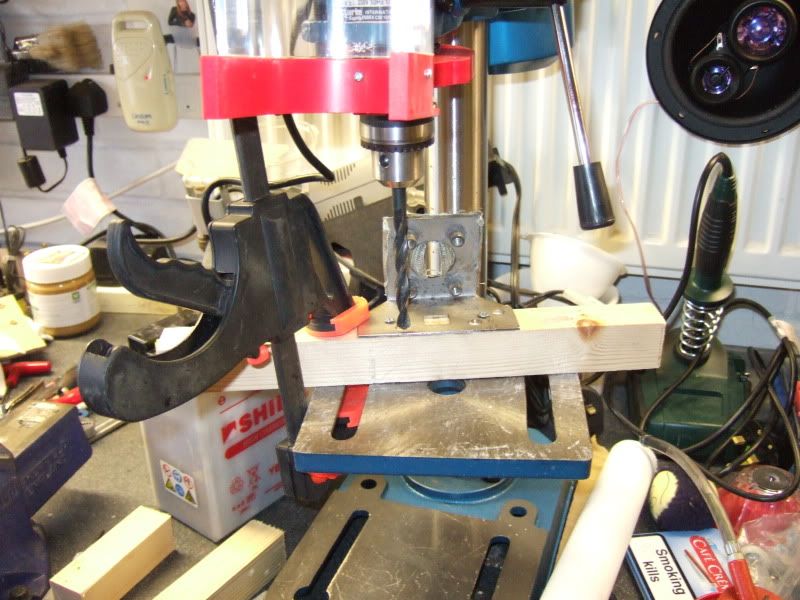

Drilling the mounting holes in the stainless was a bastard, but easier with the pillar drill than trying to do it with a hand drill.

Must invest in a proper drill clamp...

Brackets cut, holes drilled, all fingers still attached, welded in place

Next up was the removal of the headlight bracket and the addition of lock stops as the Exup bottom yoke's stops are in a different place to the FZ.

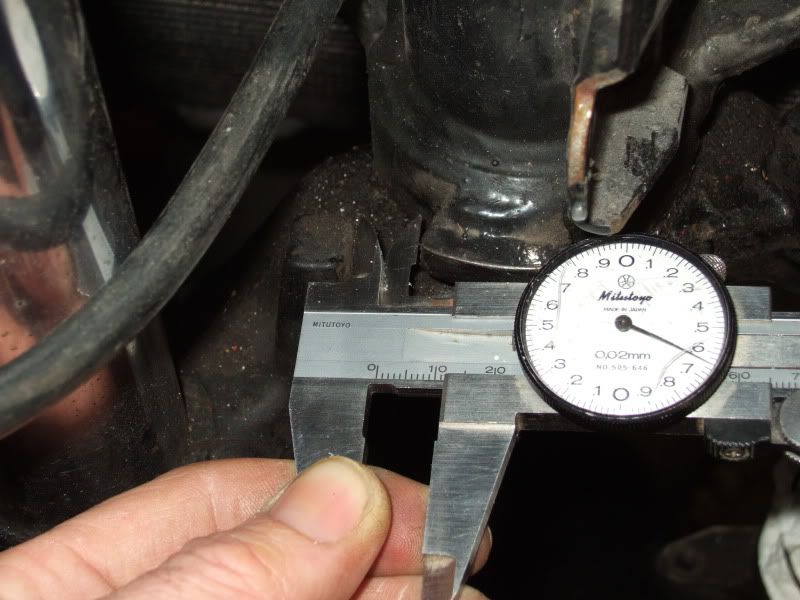

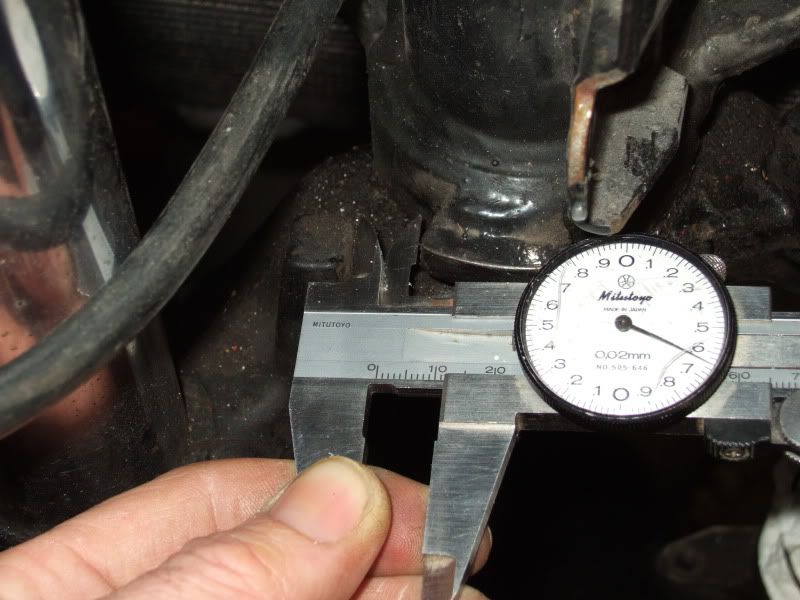

This is with the forks touching the rad, as you can see, nowhere near the stops.

about 11mm extra needed

So back to my bucket of lopped off parts, and a suitably thick piece of metal selected

Just doing my bit to recycle

Headlight mount off, smoothed down, lock stops added, wider than needed but I can adjust (grind down) them once the Rad and forks are fitted.

And that is all the frame fabrication done, as far as I can see, obviusly I will need to add the odd bracket for relays etc, but wont know where these have to go until I get to that stage.

So I got the soapy water out and gave the frame a clean, if its warm enough tomorrow I'll give it a quick coat of paint over the bare metal for protection as I cant see it being powder coated this year.

So jobs for tomorrow are, paint frame, change fork seals (had them 2 Years) and maybe start swapping front and back end over, just a rough fit as I will want to change headbearings etc, but you know how it is!!!!

As I'm sure, like me, your all fed up seeing a naked frame, unless it has tits of course!!

PS i forgot to take pics of the rear seat hump bracketry yesterday so here's a couple today, as you know I love pictures!!!

Makes a hell of a difference to the overall appearance of the machine...lots more modern