Refurbing my EXUP

Just got it fired up, sounds sweet as fook. Filled the garage with some pretty noxious fumes,  . Revs out nicely. Makes me realise how sanitised my FZ1 sounds (even with a decat and airbox mod).

. Revs out nicely. Makes me realise how sanitised my FZ1 sounds (even with a decat and airbox mod).

A few bits to tweak before carbs are secured.

Does anyone remember what car rad cap fits (is it a mazda or a mitsu?), the rad cap rubber is in an awful way and I don't want to chance it causing major heart ache.

A few bits to tweak before carbs are secured.

Does anyone remember what car rad cap fits (is it a mazda or a mitsu?), the rad cap rubber is in an awful way and I don't want to chance it causing major heart ache.

Things are getting done at a steady pace on the old girl.

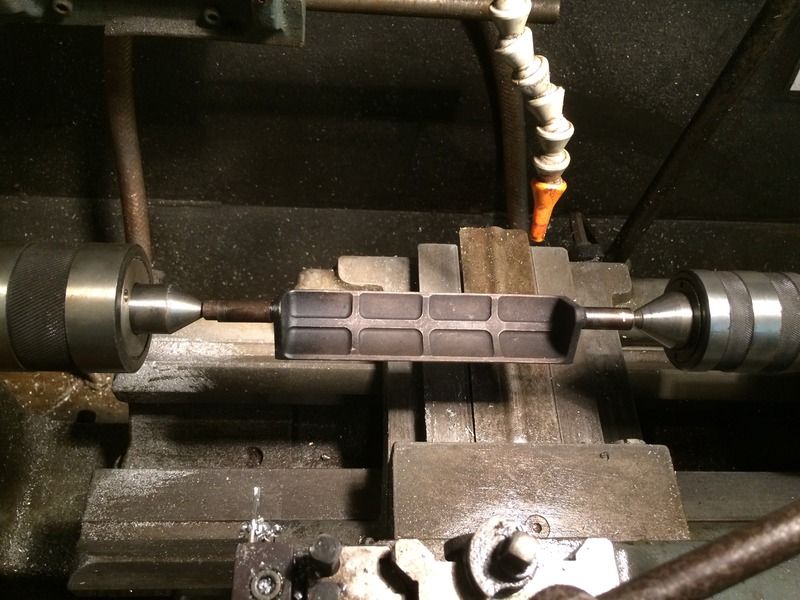

Pulled the downpipes off, so as to make sure the EXUP valve was fully functional. As it was it was not free, so the usual strip down was commenced--

After getting it all apart I retapped the cover holes and regreased the bushing with ceramic grease.

The trouble is on reassembly when I tighten the cover down the valve (which turns freely when the cover is down all the way) it binds. I checked the bushing on the far side, it's smooth and free of swarf and debris. As far as I can tell the valve is straight (if I get chance at work I will set it in a vee block and check for sure).

Is there anything else to look for that might make it bind-up. I've rebuilt a few over the years and not had this happen before. I don't think i ever been this fastidious about an exup rebuild either, yet it's giving me the most agro, any advice would be much appreciated....

Pulled the downpipes off, so as to make sure the EXUP valve was fully functional. As it was it was not free, so the usual strip down was commenced--

After getting it all apart I retapped the cover holes and regreased the bushing with ceramic grease.

The trouble is on reassembly when I tighten the cover down the valve (which turns freely when the cover is down all the way) it binds. I checked the bushing on the far side, it's smooth and free of swarf and debris. As far as I can tell the valve is straight (if I get chance at work I will set it in a vee block and check for sure).

Is there anything else to look for that might make it bind-up. I've rebuilt a few over the years and not had this happen before. I don't think i ever been this fastidious about an exup rebuild either, yet it's giving me the most agro, any advice would be much appreciated....

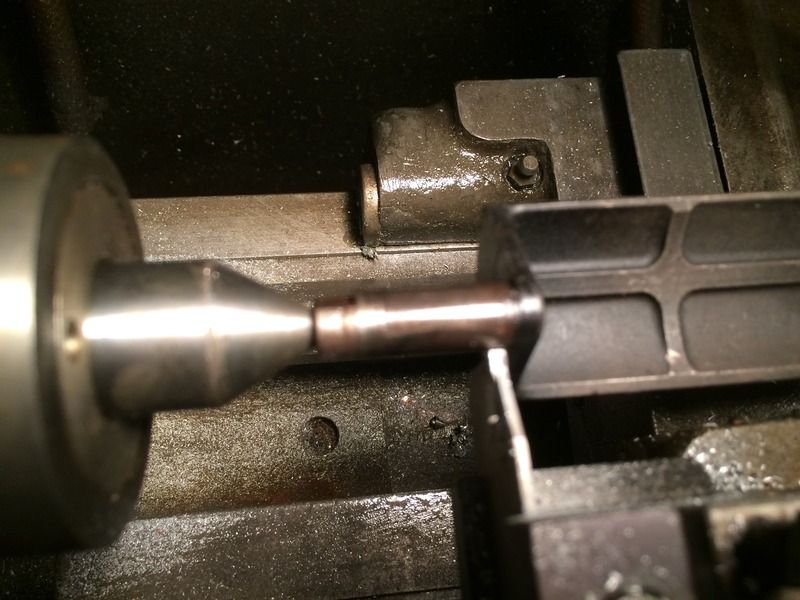

If you have access to a lathe put the valve between centres and rotate by hand. You can then either use a dial guage or I use a pointed lathe tool to test against the shaft. It takes a few goes of taking the valve out the lathe and holding it in a vice to tap the shaft in the required direction

Btw, you only just need enough pressure against the ends of the valve to hold it in situ... if you give it too much pressure the valve end will flex to give a false reading

Btw, you only just need enough pressure against the ends of the valve to hold it in situ... if you give it too much pressure the valve end will flex to give a false reading

AKA Bald headed b'stard

Thanks for the advice.

Finally got chance to take it into work today. Put it in the lathe chuck and then set the tool so I could see the run-out. Was 4mm! not wonder it was binding up. Carefully retrued it.

Then put it in a vee block and check the vertical and lateral displacement. Got it down to about 0.25mm.

Just reassembled it and not binding whatsover.

Thanks chaps.

Finally got chance to take it into work today. Put it in the lathe chuck and then set the tool so I could see the run-out. Was 4mm! not wonder it was binding up. Carefully retrued it.

Then put it in a vee block and check the vertical and lateral displacement. Got it down to about 0.25mm.

Just reassembled it and not binding whatsover.

Thanks chaps.

Who is online

Users browsing this forum: Ahrefs [Bot] and 1 guest